Unmatched Stability & Performance

for Dynamic Environments

Five Star® Precision Epoxy Grouts create a stable and durable base for high dynamic load transfer in environments subject to vibration or impact. Also, these easy-to-use, reliable grouts maintain their consistency and quality without shrinking from the time of placement. Moreover, exceptional technical support backs every installation stage, ensuring project success.

Unique Features:

- Expansive, Non-Shrink: Our grouts exhibit positive expansion, ensuring a high effective bearing area of up to 95%. This is crucial for maintaining structural integrity under dynamic conditions.

- Solvent-Free, Precision Epoxy Grouts: These grouts are tailored for challenging environments, engineered for long-term durability and precision. They are suitable for a wide range of applications.

Recommended Applications:

- Ideal for High Dynamic Loading: These grouts are ideal for applications that require long-term alignment under vibration or impact, ensuring lasting stability and performance. They also offer excellent chemical resistance.

- Specific Applications Include:

- Infrastructure and Heavy Machinery: Essential for bridge bearings, chemical tanks, compressors, and crane rails, where stability is critical.

- Industrial Equipment: Optimal for crushers, grinding equipment, mechanical rotating equipment, and presses, ensuring reliable operation.

- Dynamic and Static Loads: Ideal for fans, motors, pumps, and skid-mounted equipment, providing a stable foundation that supports both dynamic and static loads.

- Precision and Stability Needs: Crucial for post-installed anchor bolts, rotating equipment foundation rebuilds, and woodyard machinery, where precision and stability are paramount.

Related Products:

Five Star® Precision Cementitious Grouts: Recommended for static or light dynamic loading and high-temperature exposure applications.

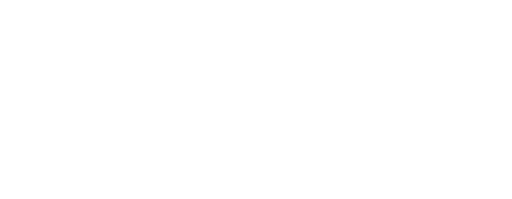

Premium Performance Epoxy Grouts

Precision, Non-Shrink Grout

Flowable Epoxy Grouts

Pump or pour with 0.4” - 9” clearances

High Early Strength Epoxy Grouts

3 hours 4,000 psi (28 MPa) to 24 hours 19,000 psi (131 MPa) @ 70°F (21°C)

High Ultimate Strength Epoxy Grouts

20,000 (138 MPa) to 23,000 (159 MPa) psi @ 70°F (21.1°C) in 28 days

High Temperature Exposure Epoxy Grouts

Temperature exposure up to 250°F

Low Exothermic Monolithic Foundation Epoxy Grouts

Up to 18” clearances

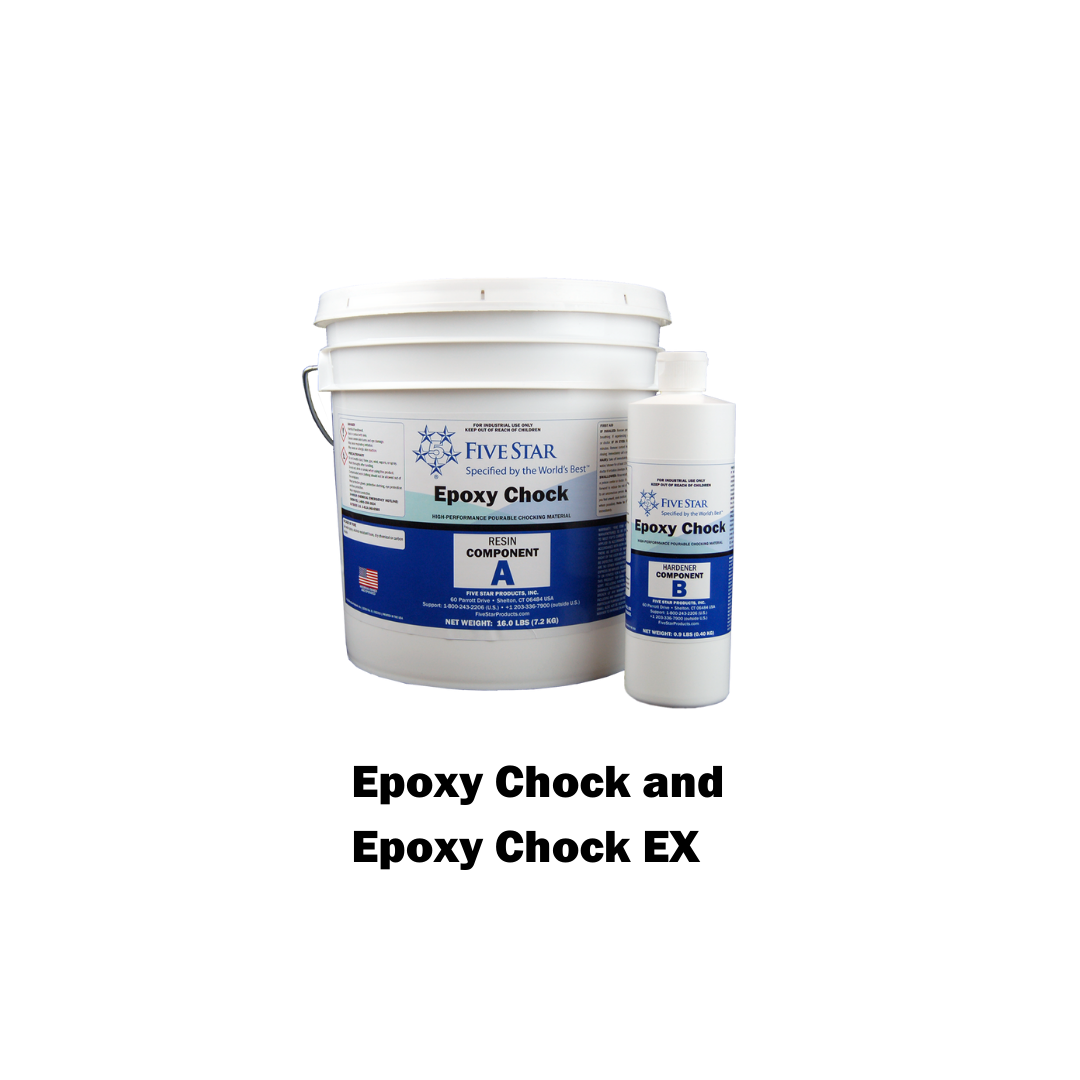

Epoxy Chocks

High-Strength, High-Temperature-Resistant Chock Systems for Maximum Stability and Reliability

Other Epoxy Grouts

Products for:

- High Chemical Resistance

- Self-Leveling for Minimal Clearances

- Marine & Wet Environments

- Electrical Resistance, Vibration, & Noise Dampening