Select Product:

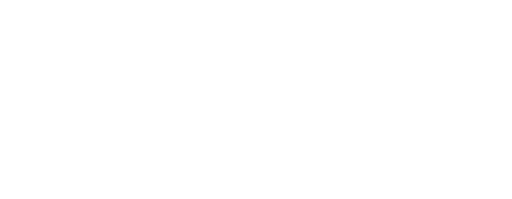

SEPTA Regional Rail Train Trestle Baseplate Repair - Media/Elwin Line, PA USA

For SEPTA's eroded railroad trestles, Five Star® Fluid Epoxy was chosen to rapidly fill voids during short, off-hours windows. The product was pre-heated to expedite curing, meeting the required strength within the tight timeframe.

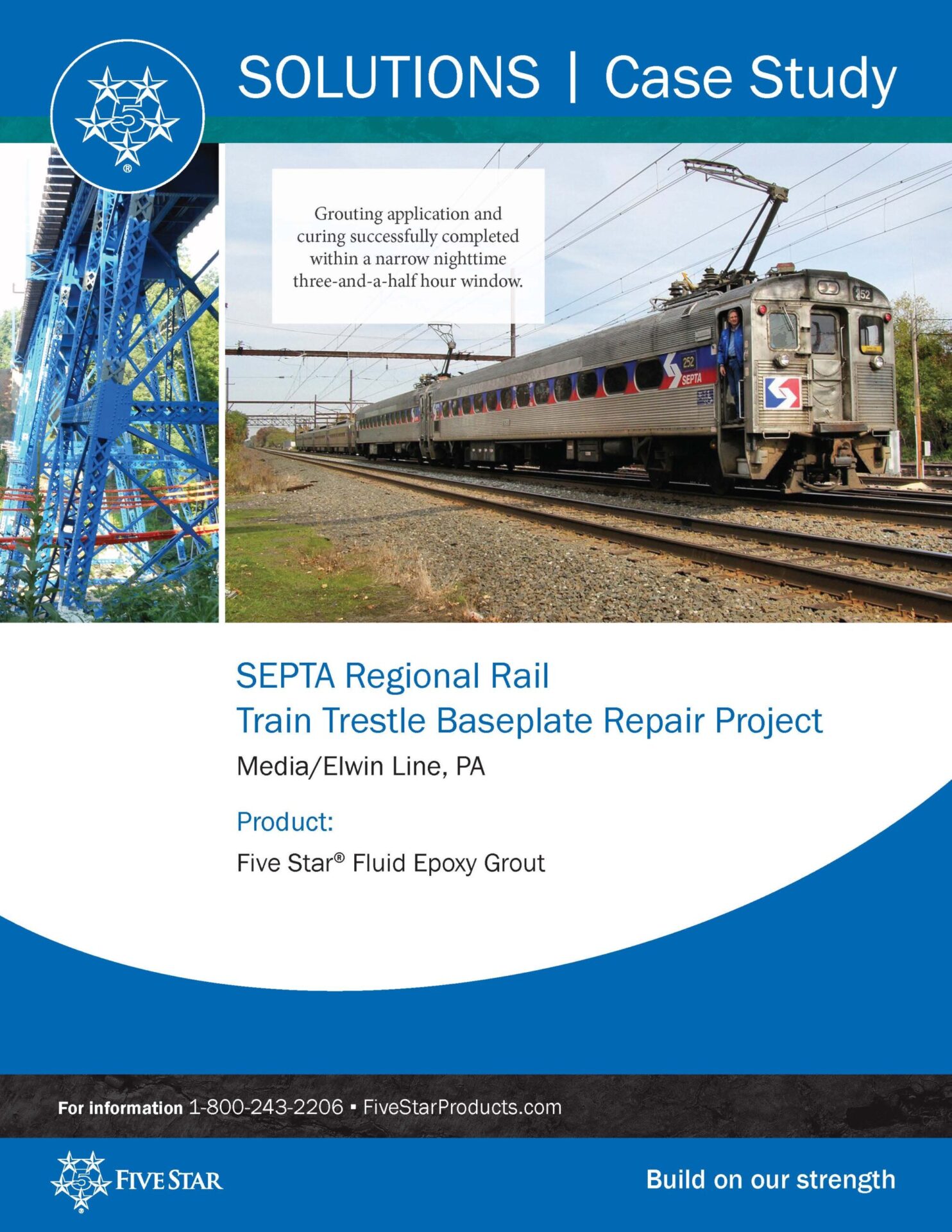

Cairns Regional Council Vertical Expansion Stormflow Joint Replacements - Queensland, Australia

For a municipal wastewater tank with deteriorated joints, Five Star Structural Concrete® V/O was used, achieving 2,500 psi in three hours, enabling swift resealing and further joint sealant installation.

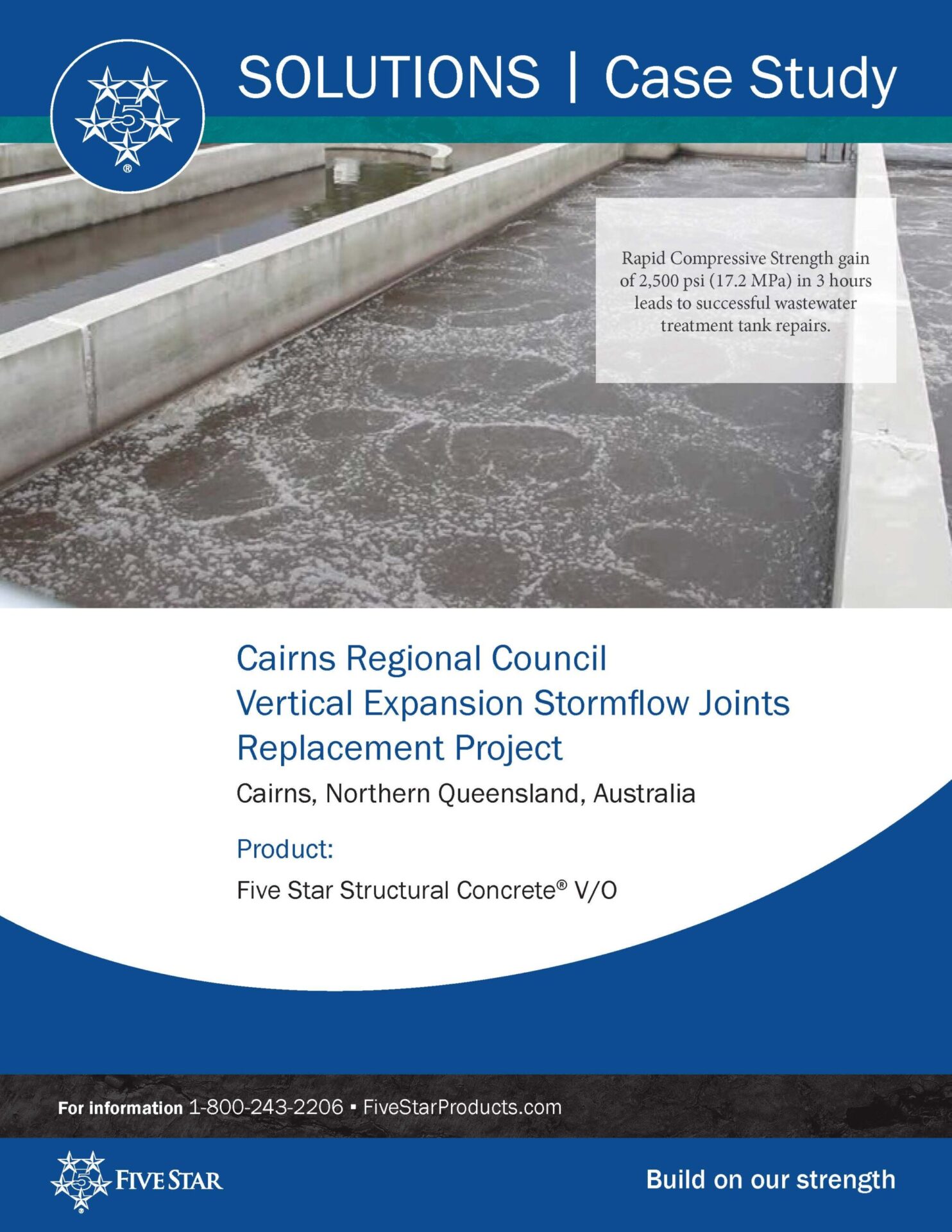

City of Greater - Victoria, Australia

Mr. Manhole used Five Star® Highway Patch for fast-setting manhole repairs in Geelong, allowing roads to reopen in under four hours, providing quality solutions more efficiently than traditional methods.

Gulf Intracoastal Waterway West Closure Project - LA USA

To support and secure the world's largest water drainage pumps in New Orleans' flood defense system, the U.S. Army Corps of Engineers relied on Five Star Products' DP Epoxy Grout for its high effective bearing area and versatile performance under extreme conditions.

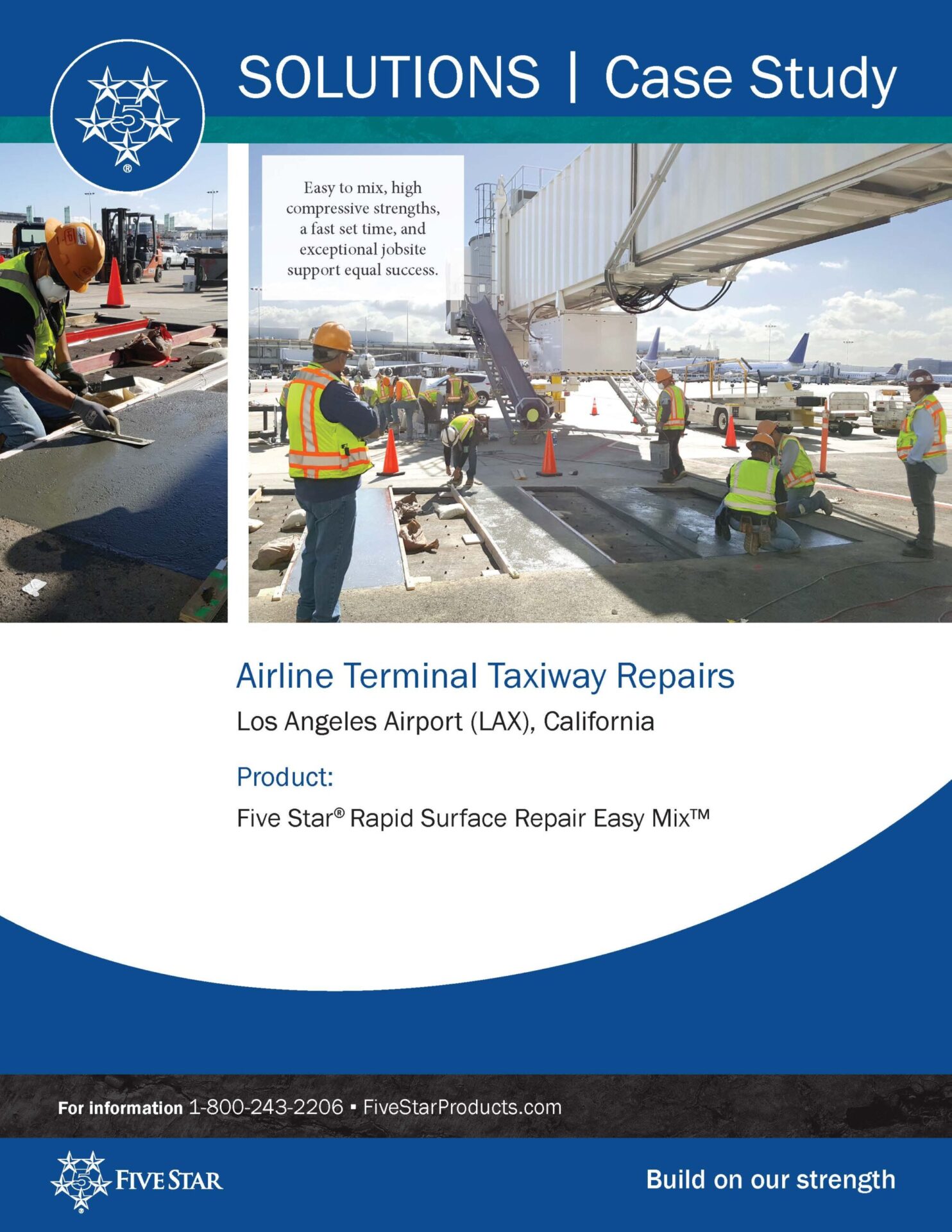

LAX Airport Taxiways Repairs, Los Angeles, CA USA

Five Star® Rapid Surface Repair Easy Mix™ swiftly addressed the taxiway's elevation misalignment at LAX, ensuring rapid set, impact resistance, and allowing the mobile bridge to operate hours after placement, completing the project in two days.

Inghams Enterprise Poultry Production Facility - Australia

Rapid Surface Repair Easy Mix™ was used at Inghams Enterprises for a quick floor repair, setting in just 10 minutes and allowing for an epoxy coating application over the weekend, ensuring the facility was operational by Monday.

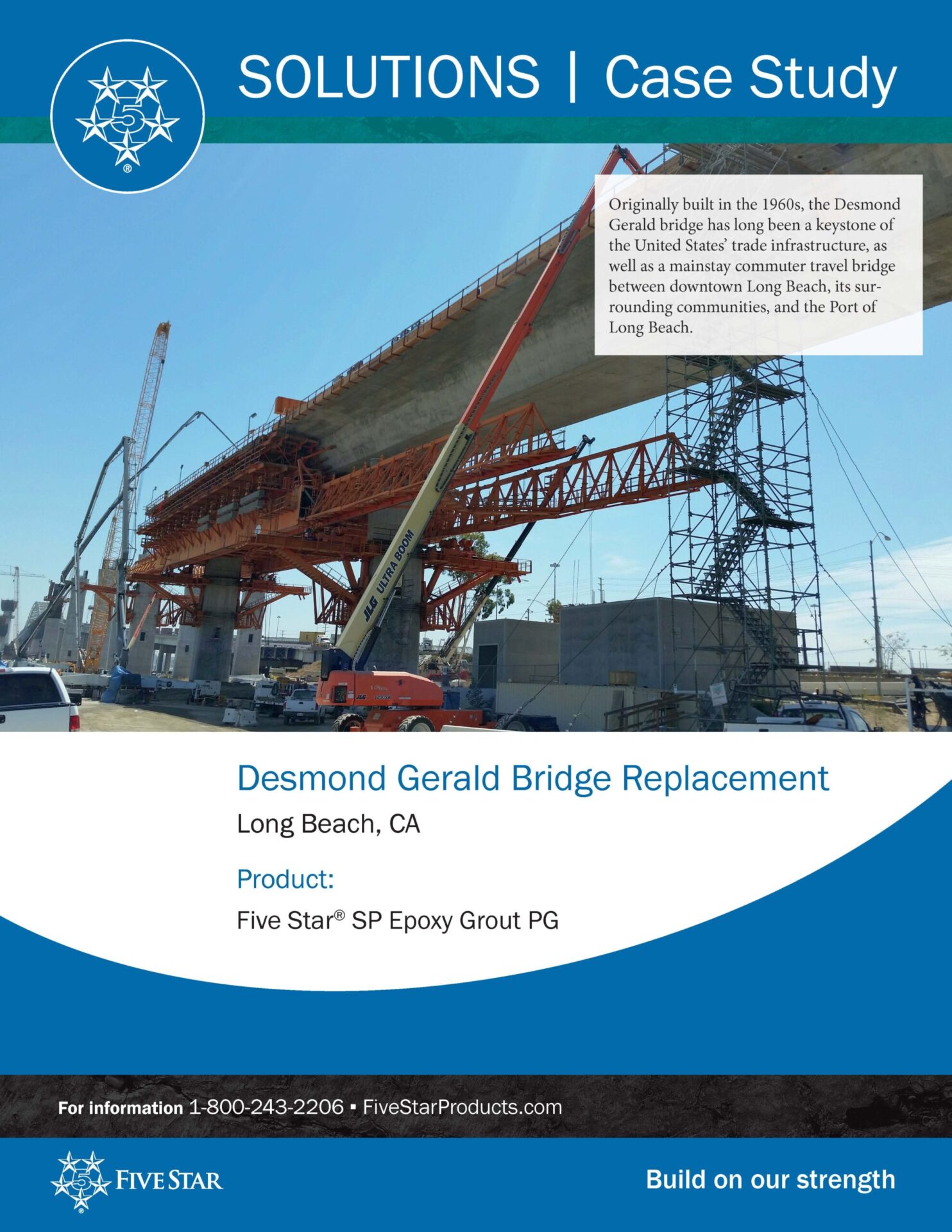

Desmond Gerald Bridge Replacement - Long Beach, CA USA

For the construction of a high-clearance bridge, Five Star® SP Epoxy Grout PG was used to securely grout crane-bearing beam pads atop towering columns, ensuring high compressive strength and rapid setting for efficient project progression.

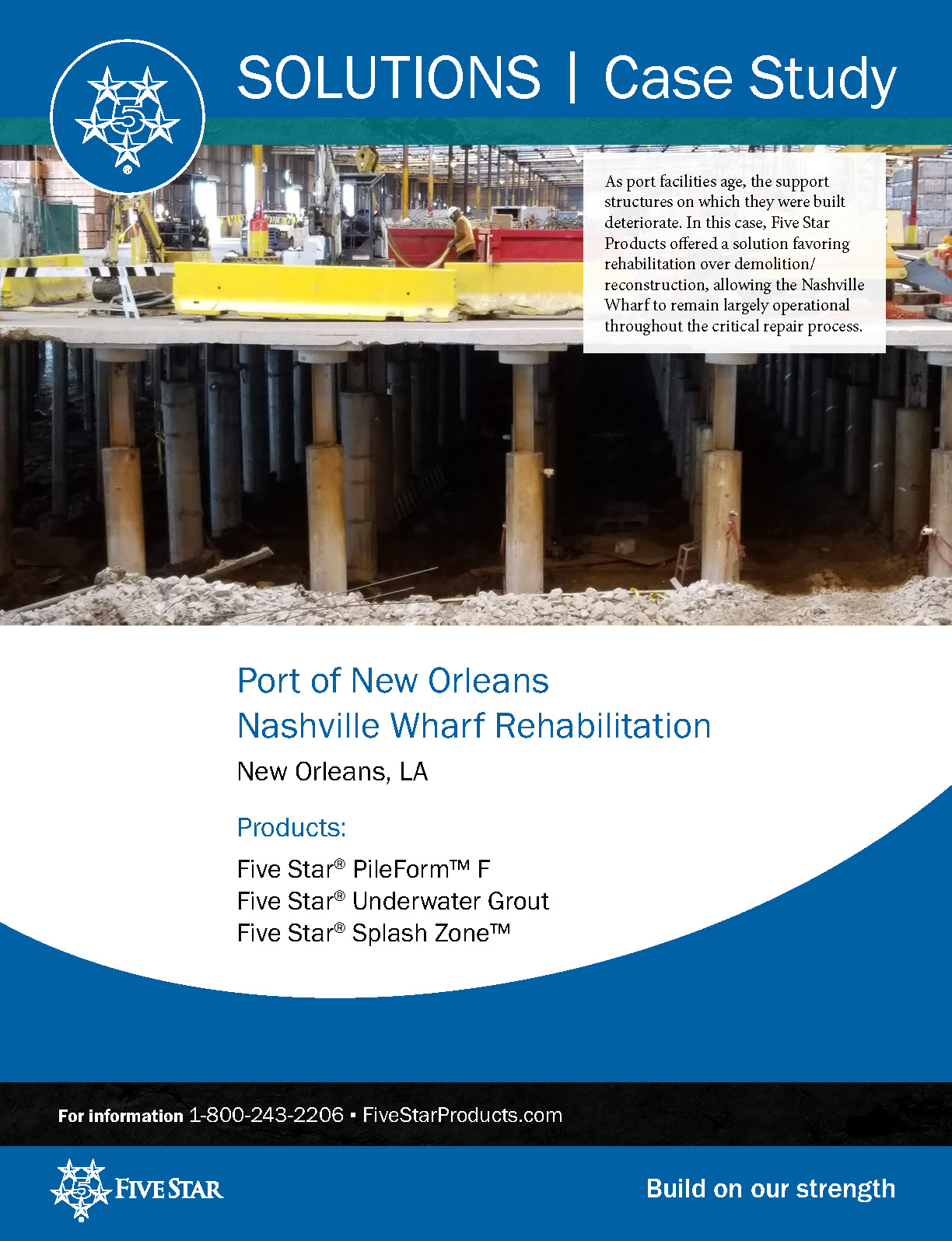

Port of New Orleans Nashville Wharf Rehabilitation — New Orleans, LA USA

Using a popular Five Star Marine restoration system, five thousand deteriorated piles were rehabilitated in this massive undertaking.

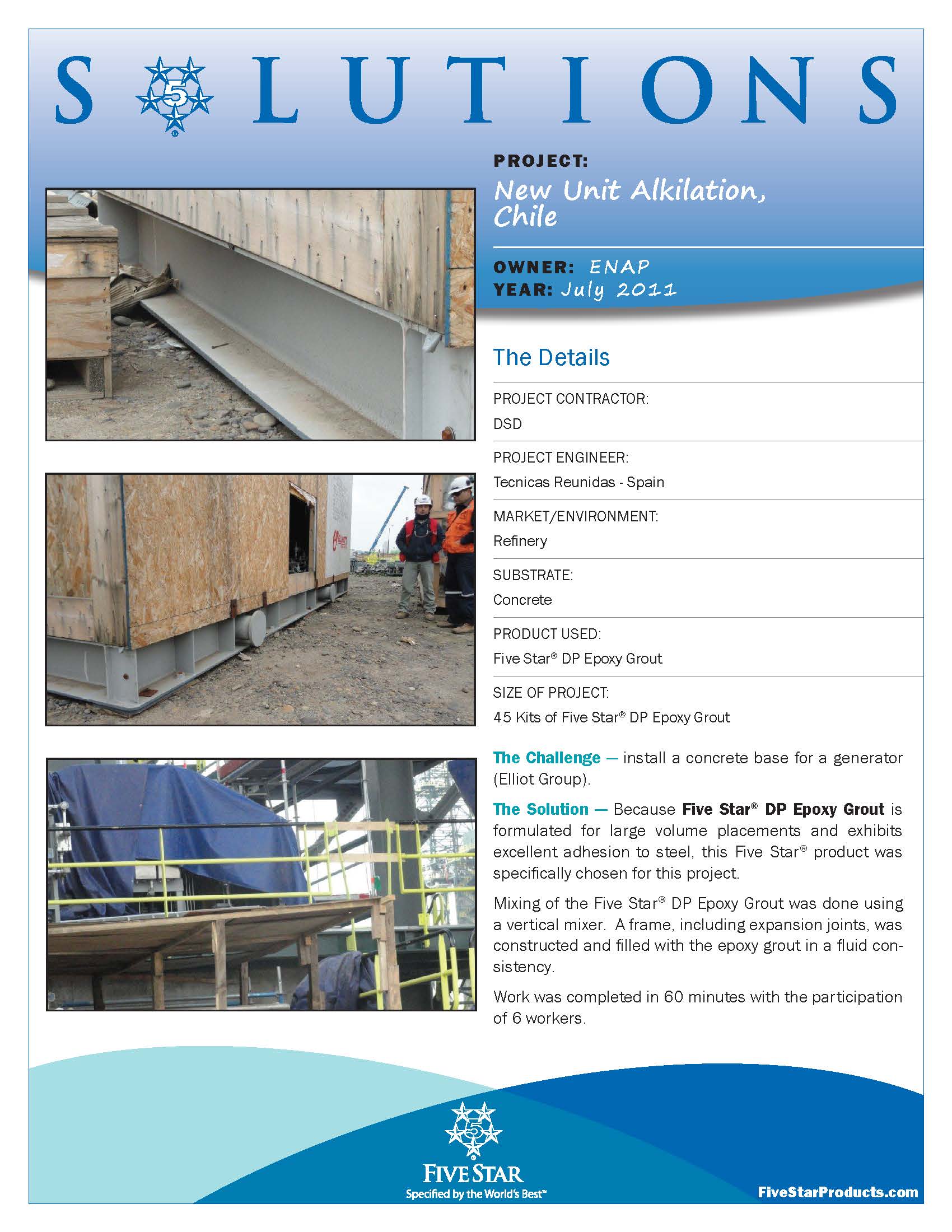

ENAP New Alkylation Unit - Chile

Five Star® DP Epoxy Grout was chosen for its large volume placement and steel adhesion capabilities to swiftly install a concrete base for an Elliot Group generator, completing the job in 60 minutes with six workers.

TATA Steel 750 ID Fan Base Plate Grouting - Labrador, Canada

To address grouting issues for TATA Steel's fan base, Five Star® DP Epoxy Grout was selected for its performance in low temperatures and superior bearing properties, successfully completing the project in two days.

KWAMNYANDU MALL, Aesthcon Construction Concrete Parking Deck Restoration - South Africa

To repair and protect the rain-damaged Kwamnyandu Mall parking deck, Five Star® Waterproofing with Migratory Corrosion Inhibitor was applied, ensuring low permeability and enhanced resistance against chloride penetration.

PASSENGER SHIP TERMINAL PIERS, Turner Construction Company Rehabilitation of Piers 88 & 90 - New York City, NY USA

To combat escalating pile degradation from marine borer activity at NYC's Passenger Ship Terminal, Five Star's PileForm F fiberglass jackets were utilized. The solution effectively shielded timber piles from marine organisms, ensuring indefinite protection with simplified installation and maintenance processes.

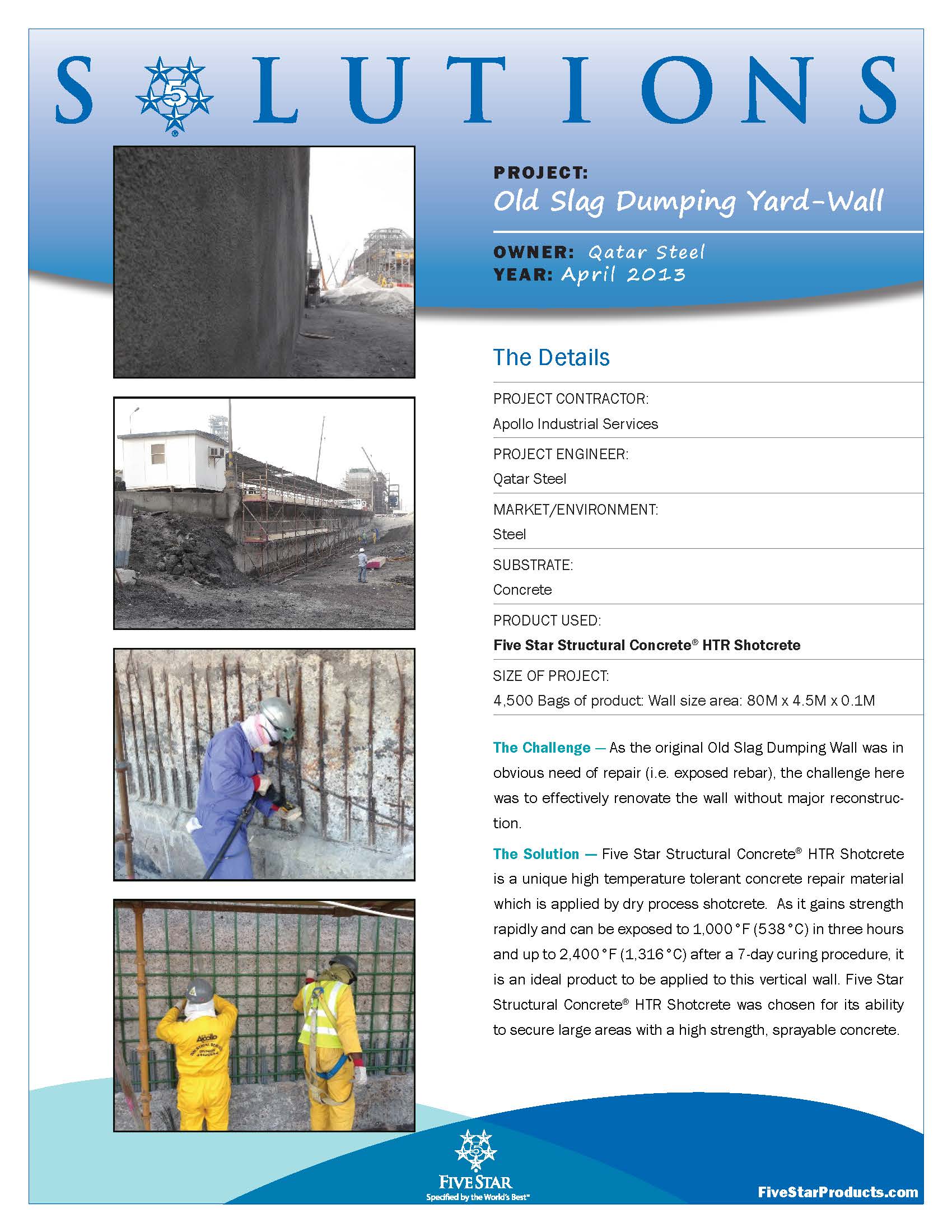

QATAR STEEL, Stoncor Mexico Old Slag Dumping Wall Repair - Mexico

To renovate the deteriorating Old Slag Dumping Wall without major reconstruction, Five Star Structural Concrete® HTR Shotcrete was utilized for its rapid-strengthening and high-temperature tolerance, enabling efficient, sprayable repairs.

Brookfield Properties Open Trench Platform Over Active Railroad - New York City, NY USA

For a challenging bridge project over Penn Station's railway tracks, Five Star® Special Grout 400 was chosen for its aptness in grouting cables, tendons, and precast panels without disturbing continuous train traffic.

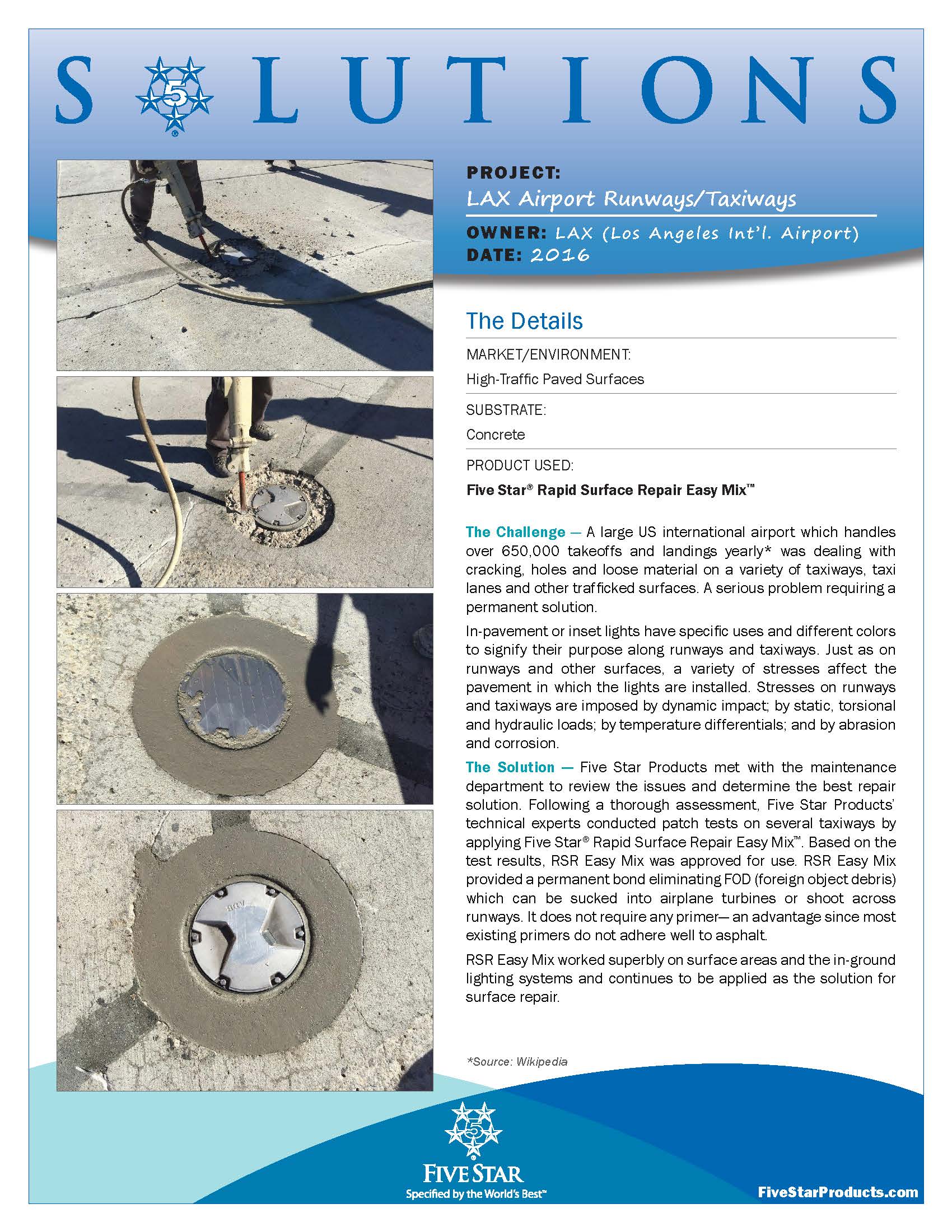

LAX AIRPORT, Airport Runways/Taxiways Rapid Surface Repair Easy Mix - Los Angeles, CA USA

Five Star® Rapid Surface Repair Easy Mix™ was utilized at a major US airport to address cracks, holes, and loose materials on taxiways and lighting systems, providing a permanent bond that prevents foreign object debris and adheres well to asphalt without needing a primer.

PETRA NOVA Project, World's largest post-combustion carbon capture plant - Houston, TX USA

Five Star Products were utilized in the Petra Nova CCS project to ensure machinery stability amidst constant vibration and pressure. Their solutions included Fluid Grout 100 for various structures and DP Epoxy Grout for vertical pumps.

THUMS Islands (Astronaut Islands) Grissom Waterfall Rehab - Long Beach, CA USA

For deteriorating concrete structures on THUMS Islands, Five Star Structural Concrete® V/O was chosen for its rapid-setting and versatility, enabling efficient repairs in both thin and thick placements despite logistical challenges.

BHP Billiton Throughput Increase - Chile

Five Star® DP Epoxy Grout was selected for its vibration dampening and high strength to grout a large rotating cylinder's mainframe, using expansion joints.

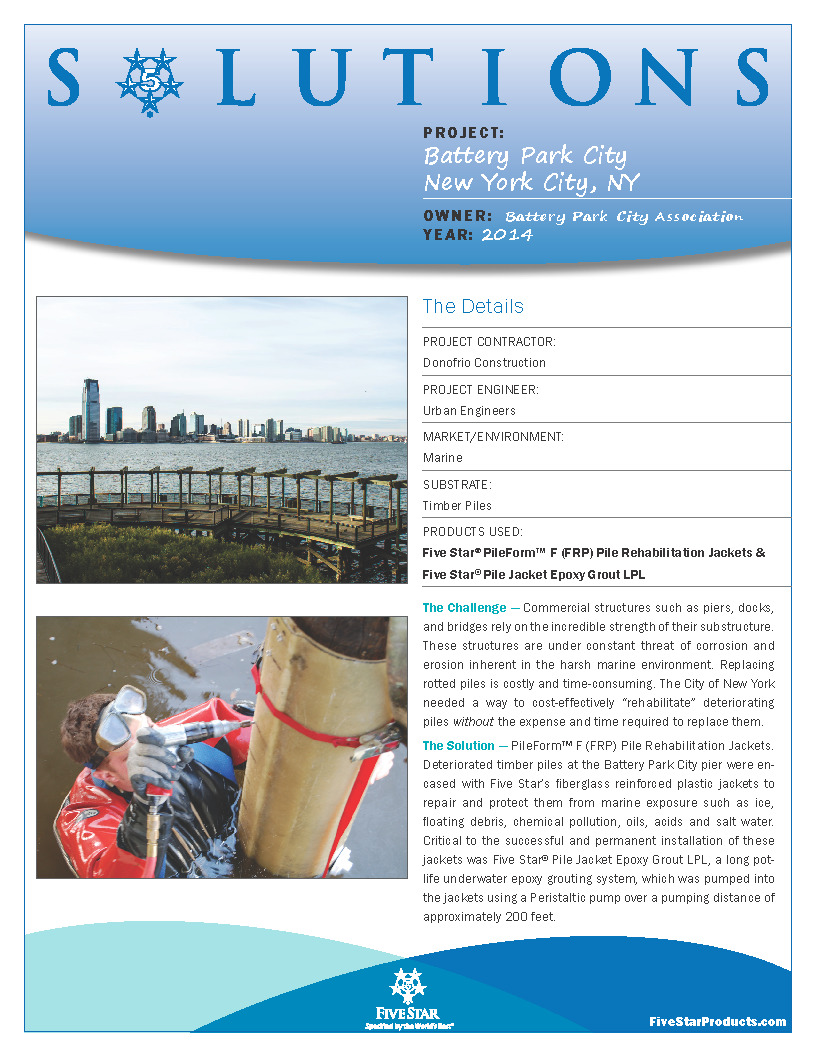

BATTERY PARK CITY, Battery Park City Association Timber Pile Rehabilitation - New York City, NY USA

The City of New York called on Five Star to cost effectively "rehabilitate" deteriorating piles without the expense of replacing them.

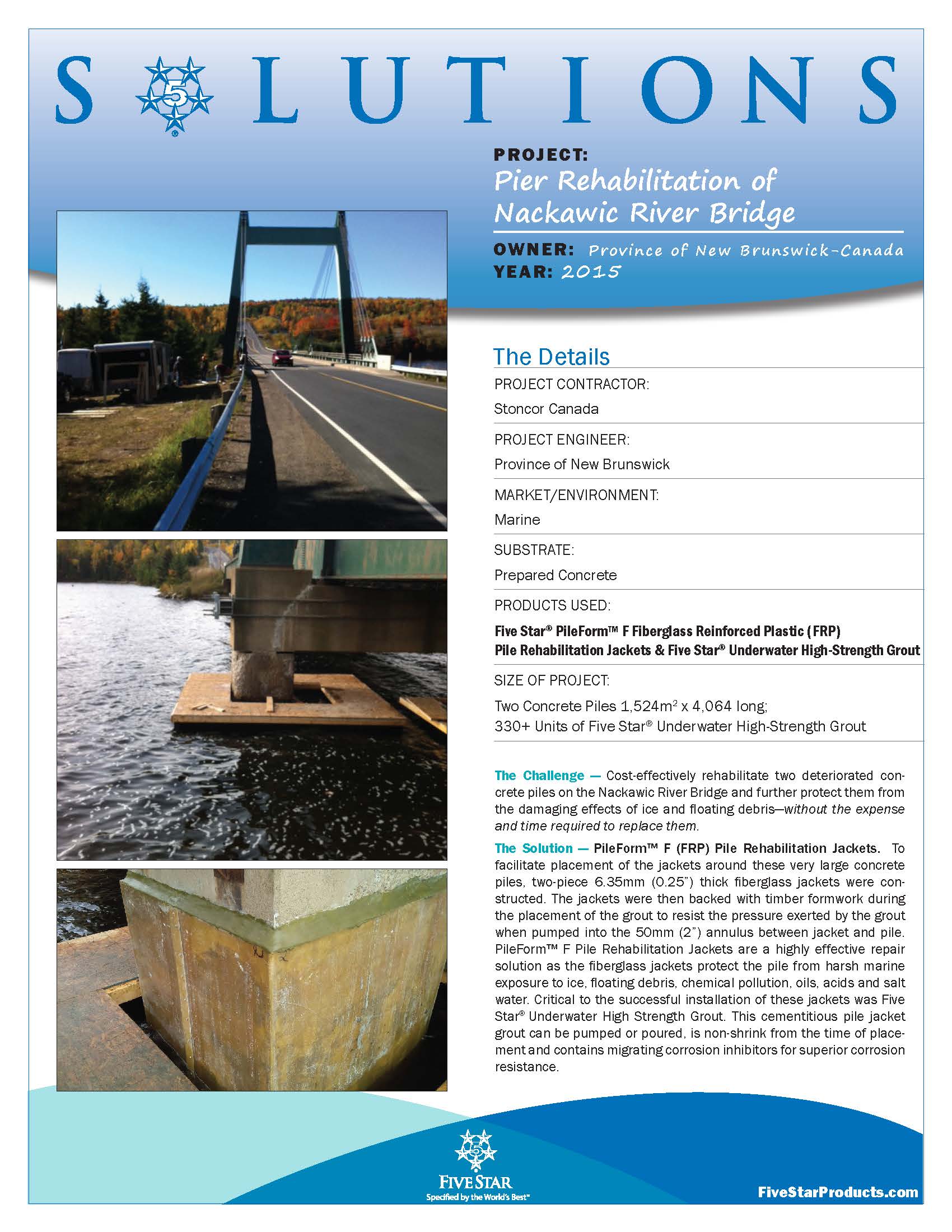

NACKAWIC RIVER BRIDGE, Stoncor Canada Pier Rehabilitation - New Brunswick, Canada

PileForm™ F Pile Rehabilitation Jackets, backed by timber formwork and filled with Five Star® Underwater High Strength Grout, were used to effectively rehabilitate and protect deteriorated concrete piles on the Nackawic River Bridge from marine damages.

MANIWAKI COURTHOUSE, Stoncor Canada Elevator Pit Repair - Quebec, Canada

To fix humidity damage in the Maniwaki Courthouse elevator pit, Five Star® Waterproofing was used, offering a moisture-resistant barrier for both horizontal and vertical applications, proving cost-effective and reliable.

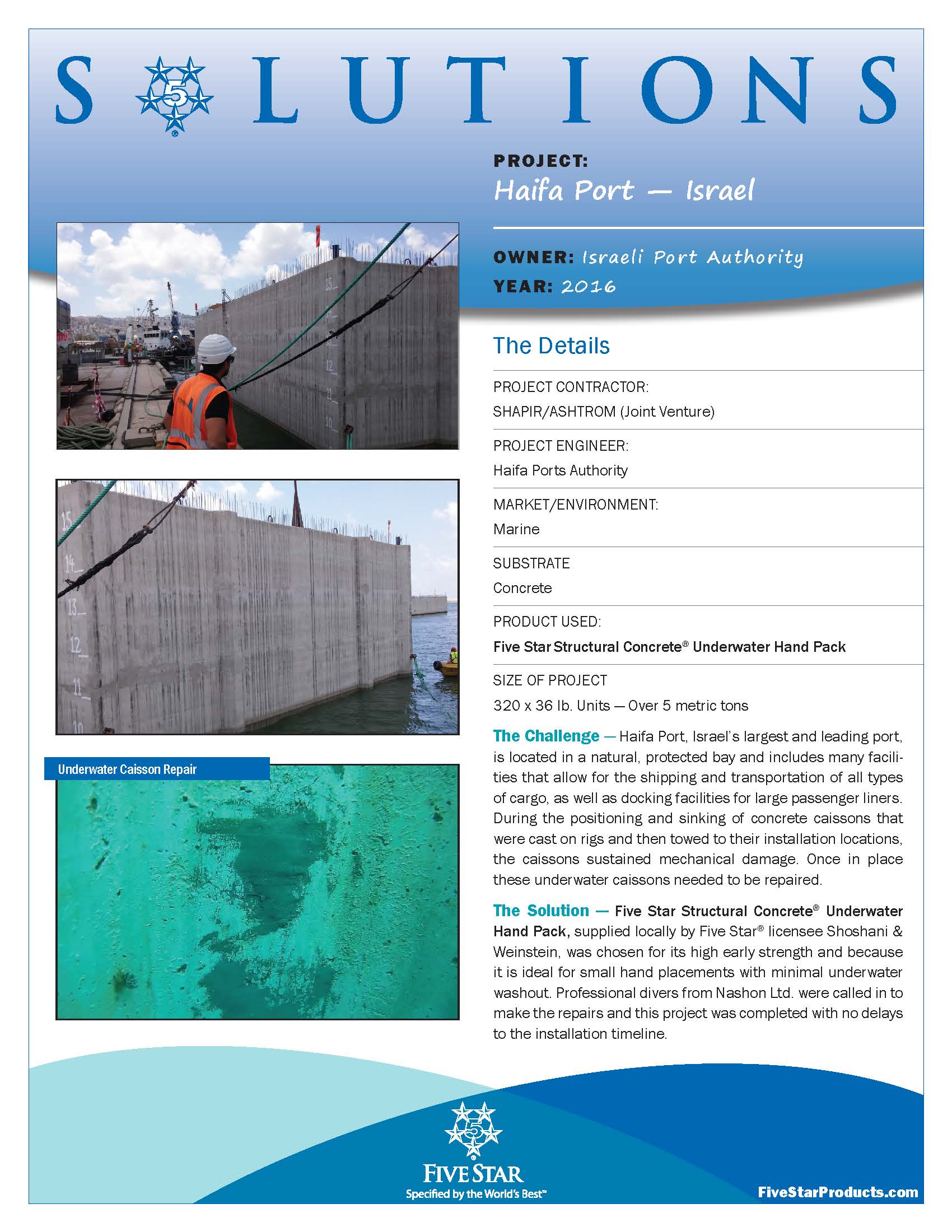

HAIFA PORT Caisson Damage Repair - ISRAEL

For repairing mechanically damaged underwater caissons at Haifa Port, Five Star Structural Concrete® Underwater Hand Pack was chosen, facilitating quick repairs by divers without delaying the installation schedule.

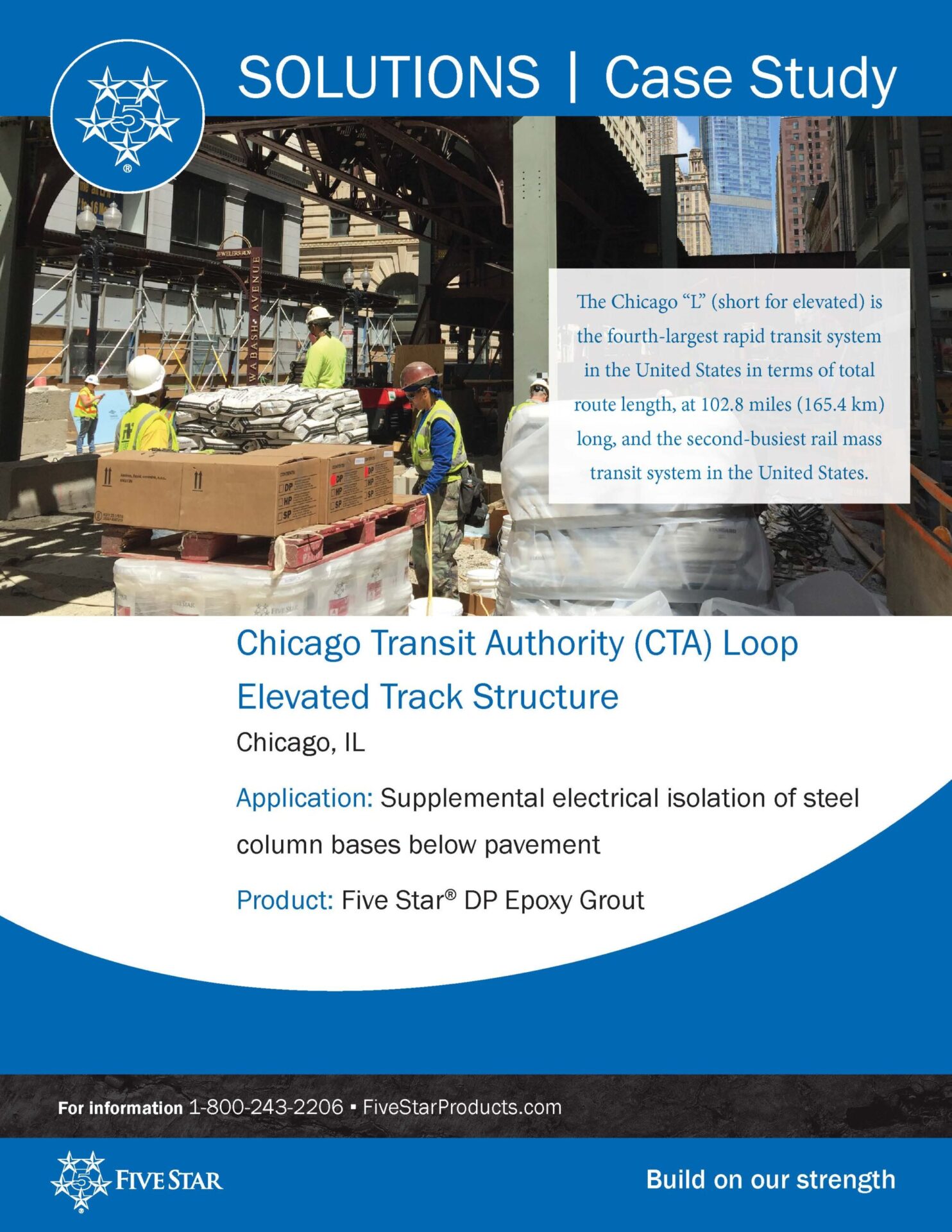

Chicago Transit Authority (CTA) "L" Track Support Beam Encapsulation Project - Chicago, IL USA

New steel beams being installed for an above-ground walkway needed to be insulated, or encapsulated, to prevent static electricity generated by the trains from transferring through the beams.

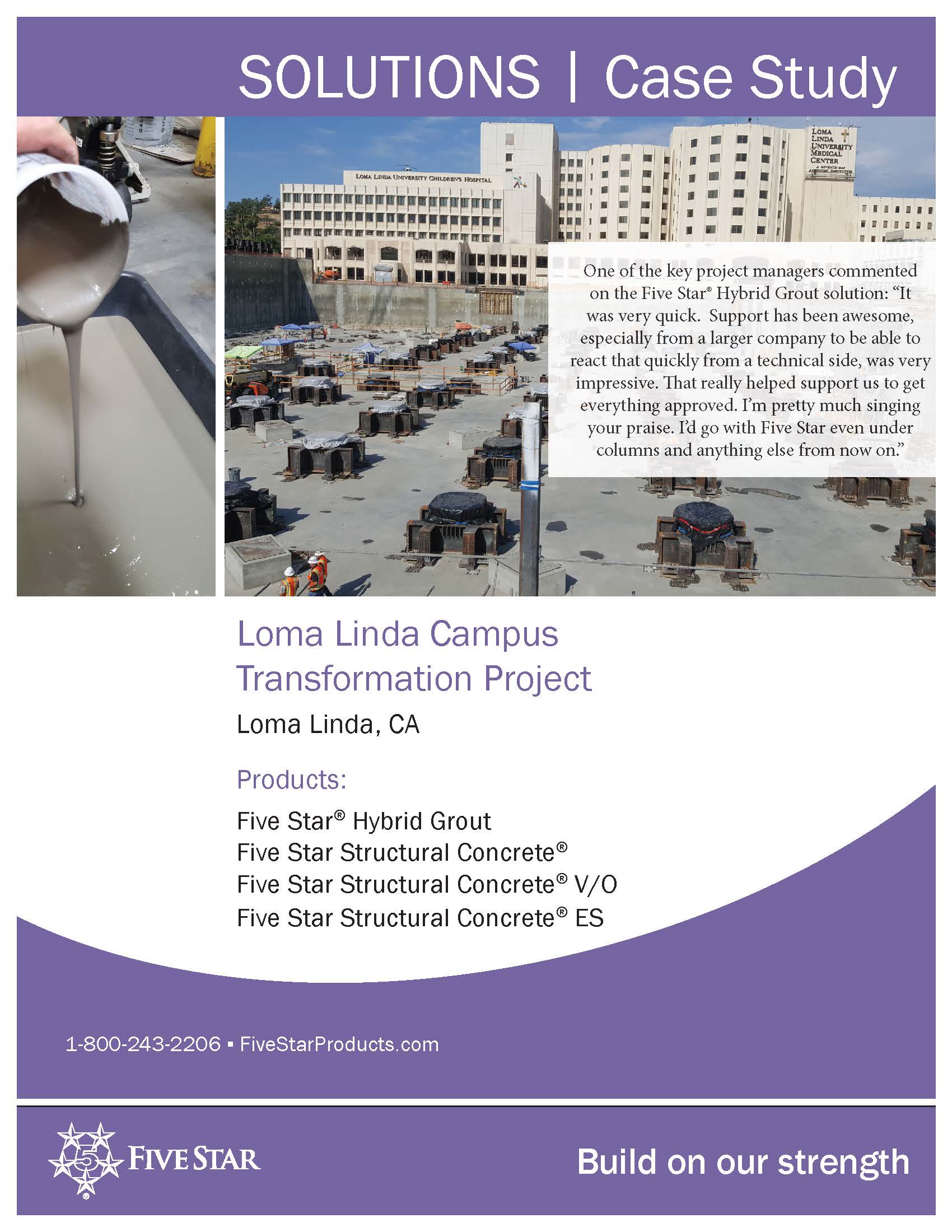

LOMA LINDA Children's Hospital Expansion - Loma Linda, CA USA

Five Star Hybrid Grout was rigorously tested and chosen for the Loma Linda Campus Transformation Project to ensure the seismic safety of the hospital's unique structure. It met stringent requirements and was applied in various critical areas, facilitating the project's expedited schedule.

Port of Brisbane Phases 1-3 - Queensland, Australia

Day and night shifts were run to complete this job with minimal downtime. Five Star® LC Epoxy Grout was selected for its ease of application and rapid strength gain, enabling efficient grouting for McMahon Services' tight schedule and contributing to the on-time completion of each project phase.

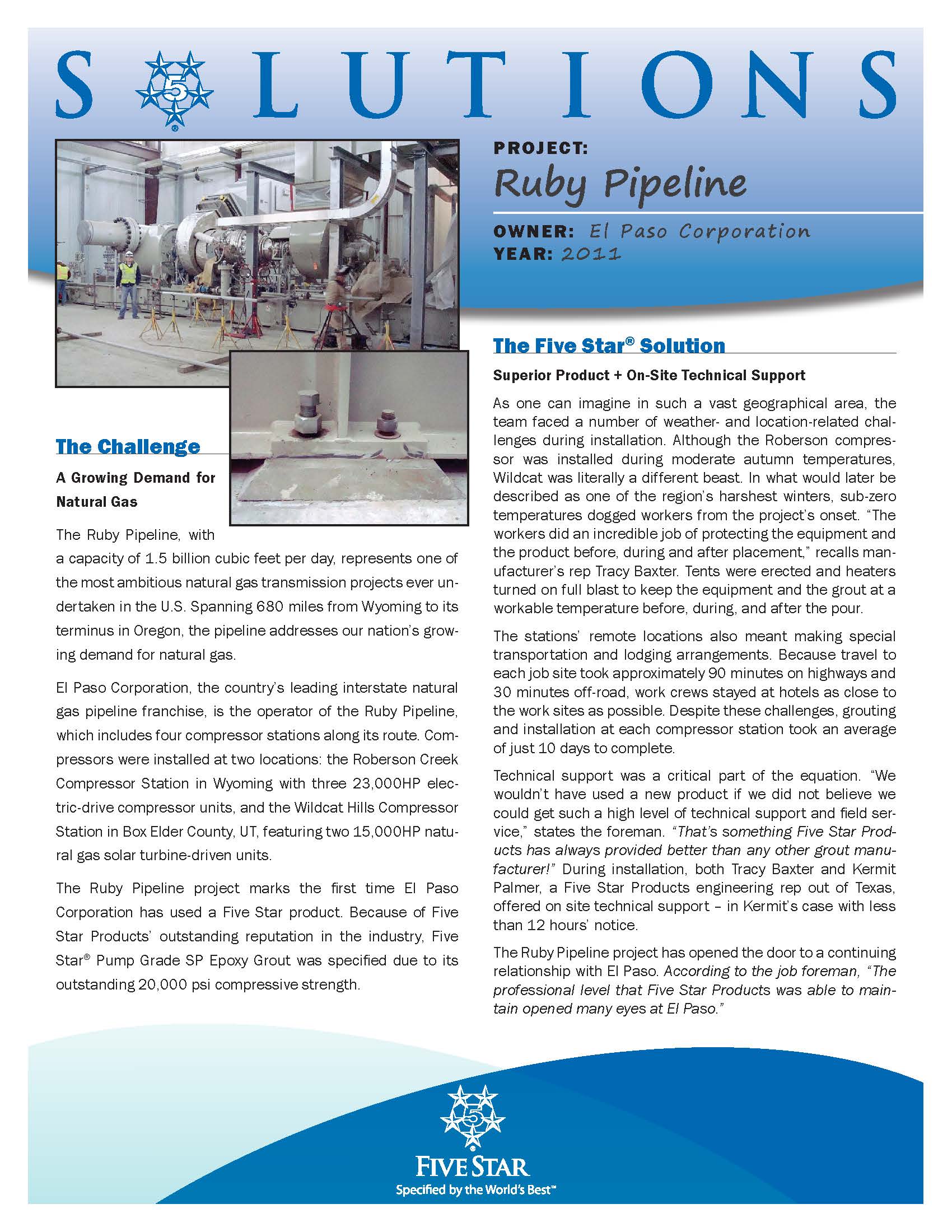

Ruby Pipeline - Wyoming and Utah, USA (12016)

For the expansive Ruby Pipeline project, Five Star® Pump Grade SP and DP Epoxy Grout were utilized for their high compressive strength, navigating severe weather and remote site challenges, with indispensable on-site technical support ensuring successful installations.

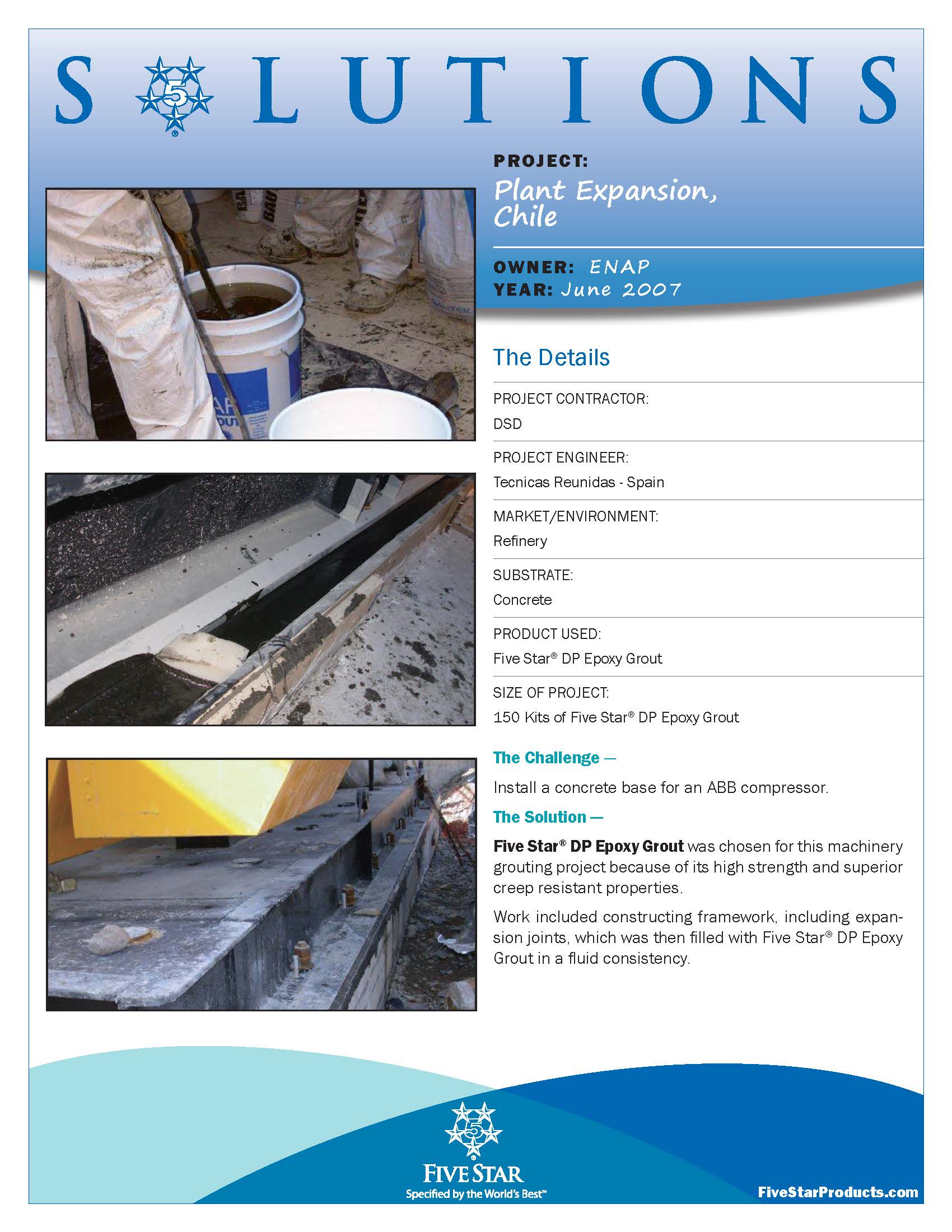

ENAP Plant Expansion - Chile

Five Star® DP Epoxy Grout was utilized to establish a robust concrete base for an ABB compressor due to its high strength and creep resistance. It involved framework construction and fluid consistency filling.

Dominion Virginia Project - Virginia, USA

Five Star® Fluid Grout 100 was utilized to securely set massive transmission towers for Dominion Virginia Power's $250 million project in Virginia's challenging terrains, with customized solutions addressing geographical and environmental concerns, ensuring the project remained on schedule.

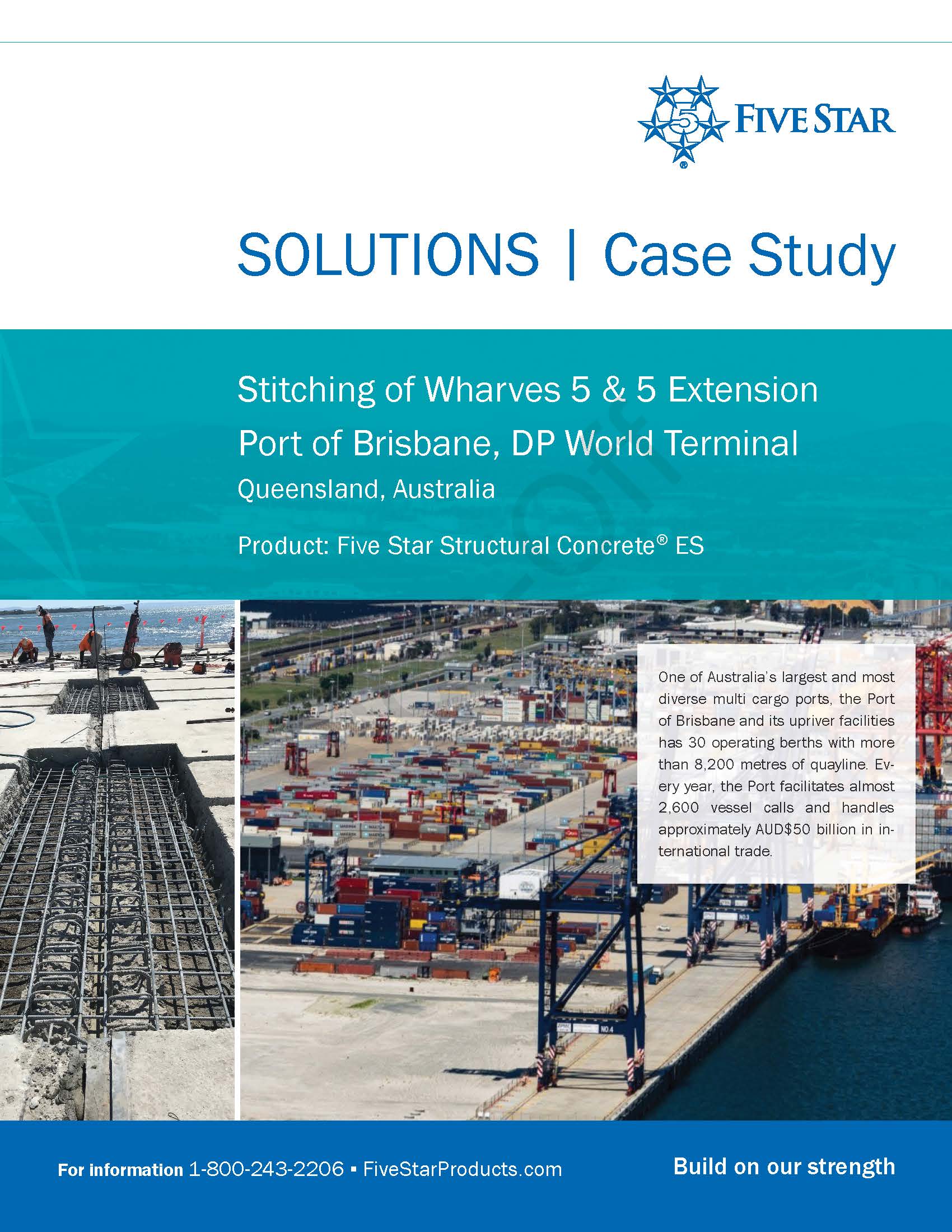

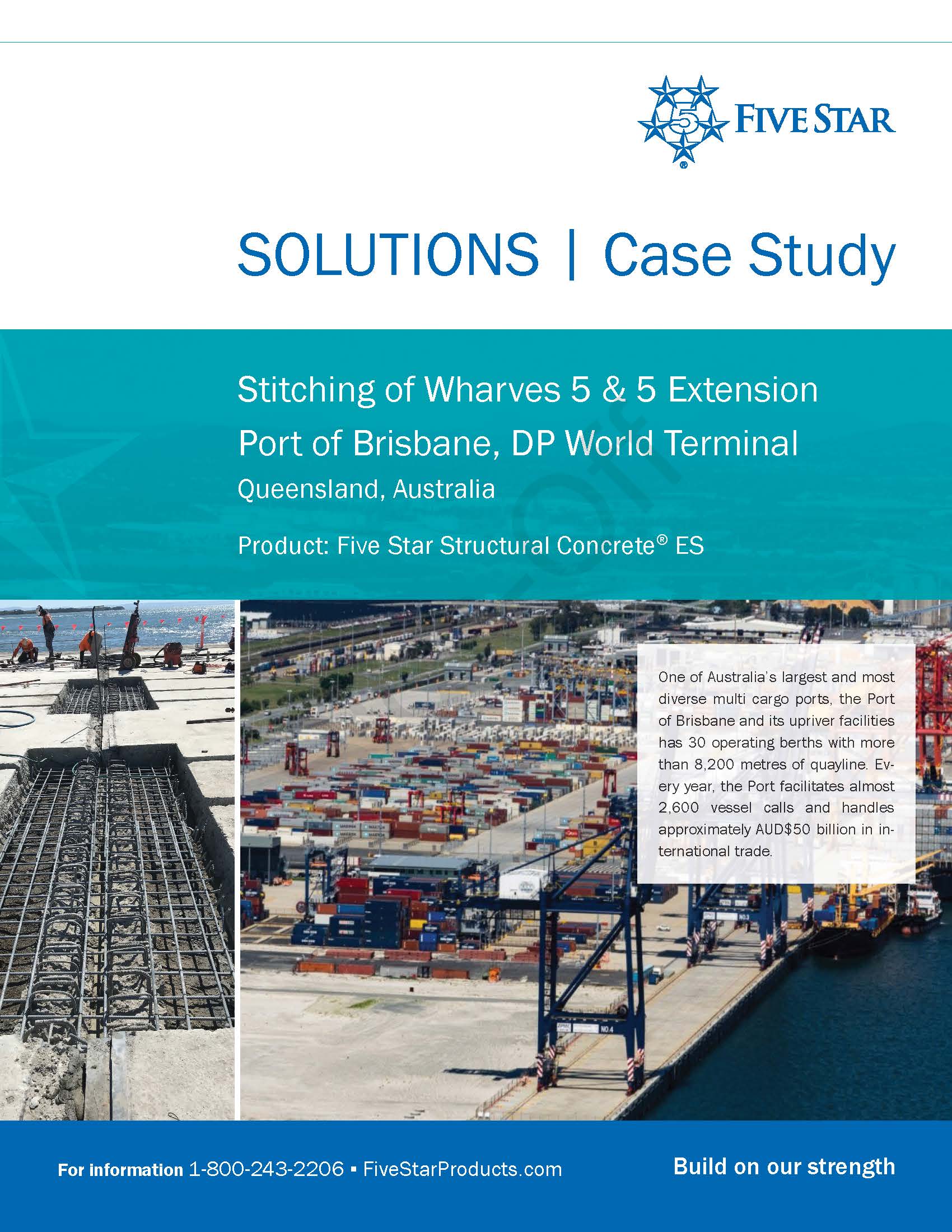

Stitching of Wharves 5 & 5 Extension Port of Brisbane, DP World Terminal - Queensland, Australia

The Challenge involved joining Wharves 5 & 5 Extension under challenging hot and windy conditions on exposed decks using sixteen stress bars. In response, Five Star Structural Concrete ES was chosen for its extended working time and consistent formulation, ensuring the project's successful completion despite the demanding weather conditions.

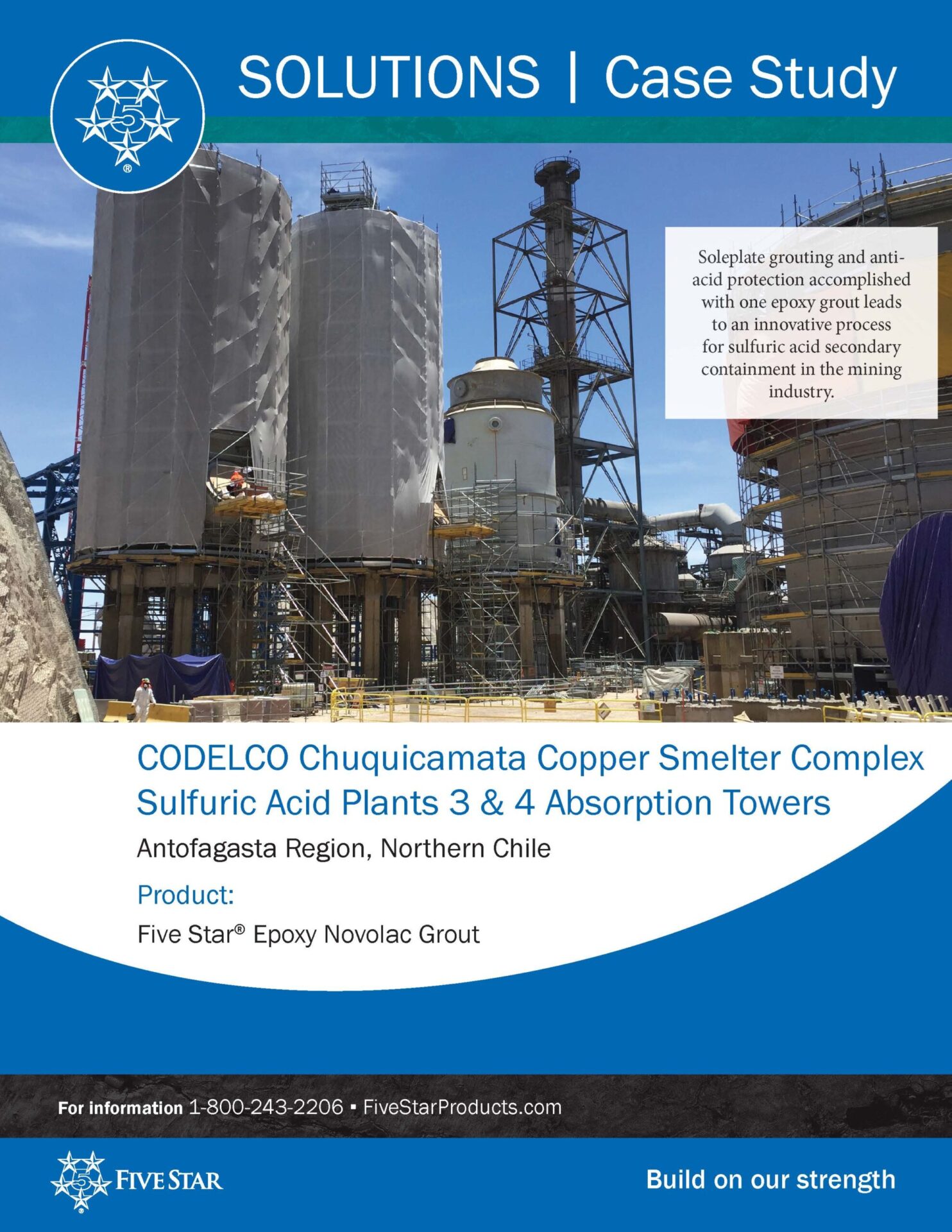

CODELCO Chuquicamata Copper Smelter Complex Sulfuric Acid Plants 3 & 4 Absorption Towers - Antofagasta Region, Northern Chile

For the Chuquicamata Copper Smelter's absorption towers, Five Star® Epoxy Novolac Grout was used both to grout the soleplate and act as an anti-acid coating, simplifying the process, reducing costs, and expediting tower readiness.

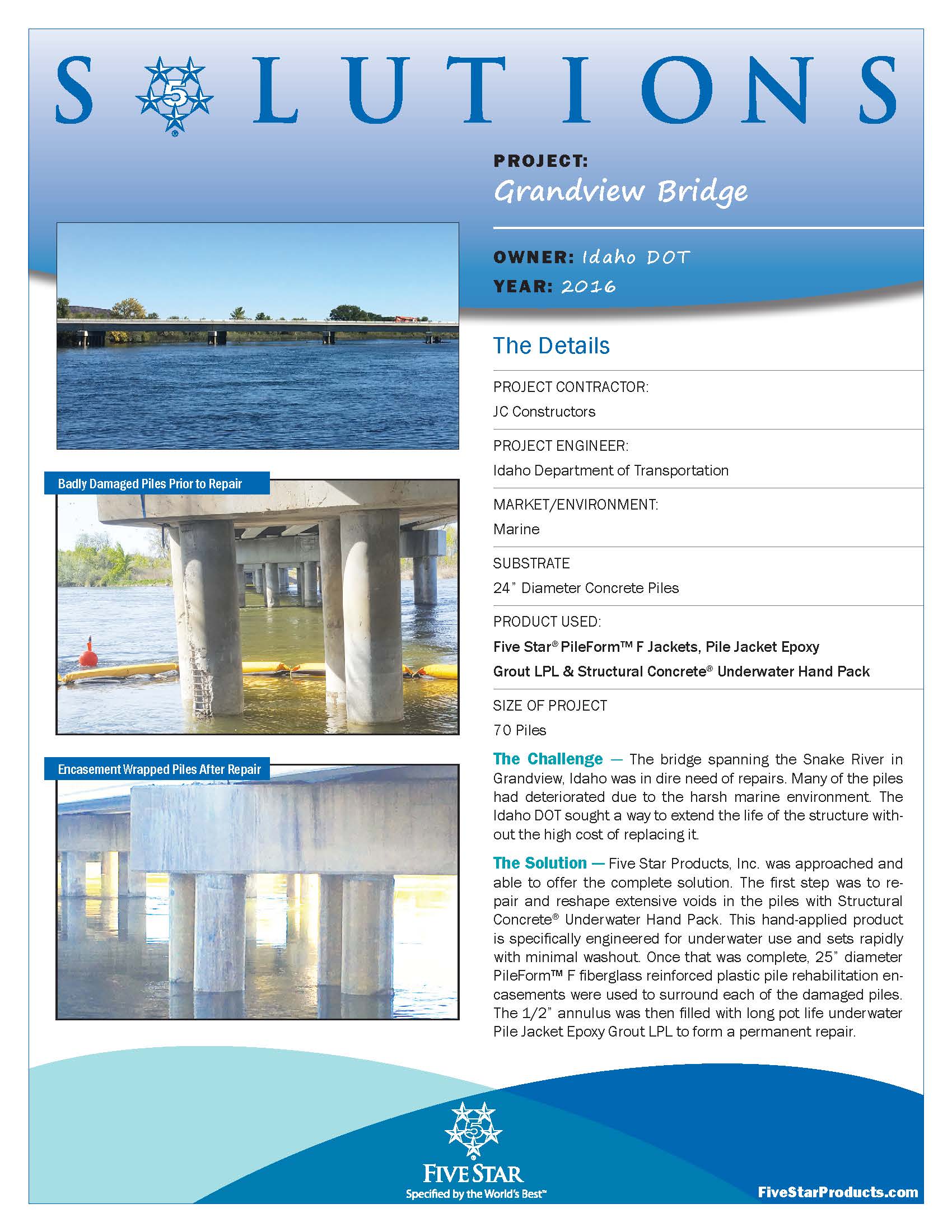

Grandview Bridge - ID, USA

To repair the deteriorated piles of the Snake River bridge, Structural Concrete® Underwater Hand Pack was applied for void reshaping, followed by PileForm F fiberglass reinforced plastic pile and Pile Jacket Epoxy Grout LPL, providing a lasting solution without pile replacement.

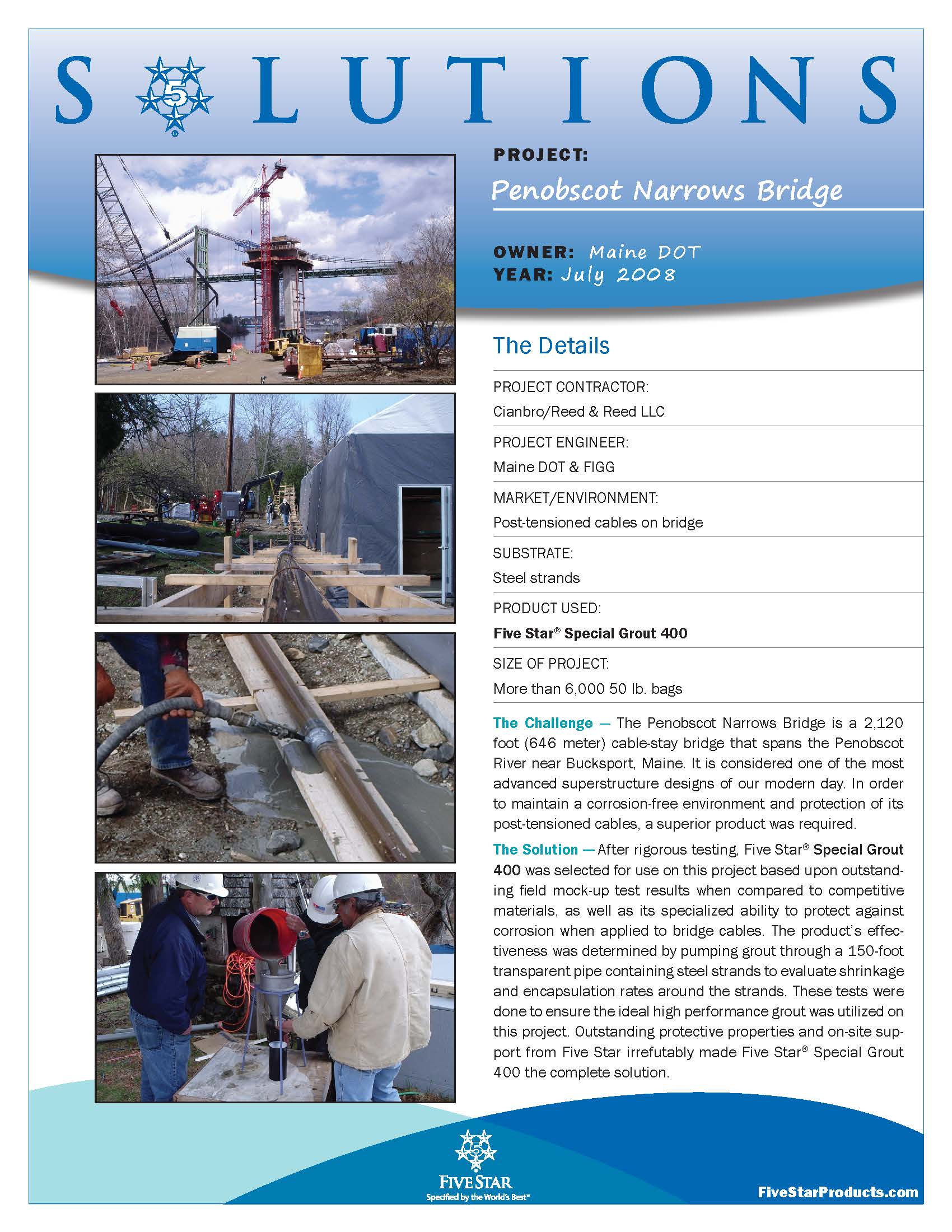

Penobscot Narrows Bridge - ME, USA

Five Star® Special Grout 400 was chosen for its superior corrosion protection and performance on post-tension cables, outperforming competitors in field tests.

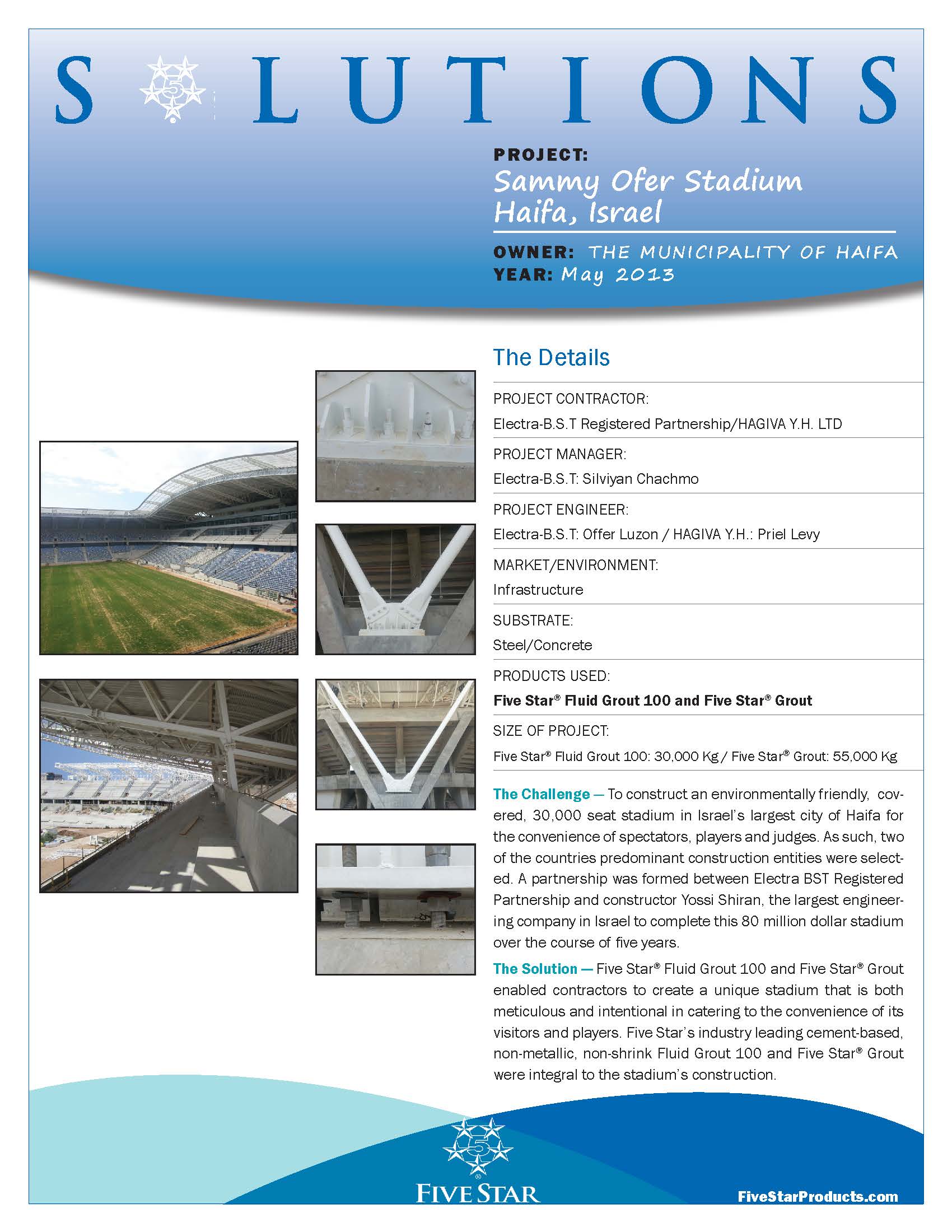

Sammy Ofer Stadium - Haifa, Israel

Five Star® Fluid Grout 100 and Five Star® Grout were crucial in constructing a meticulous, environmentally friendly 30,000-seat stadium in Haifa, catering to the convenience of its visitors and players.

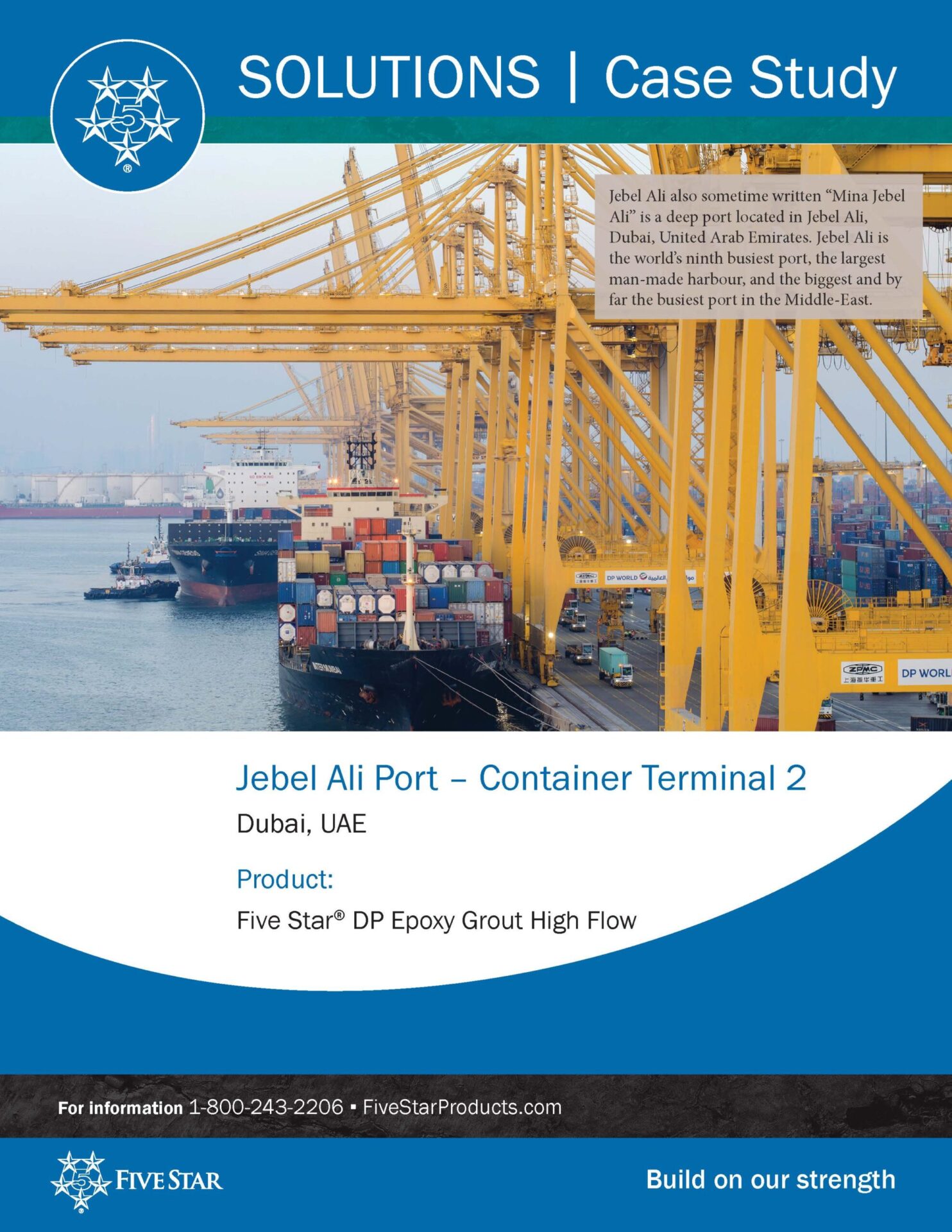

Jebel Ali Port, Container Terminal 2 - Dubai, UAE

Five Star® DP Epoxy Grout High Flow was used for its precise alignment and steel adhesion in extending the quay wall, allowing the terminal to handle more vessels and improve efficiency.

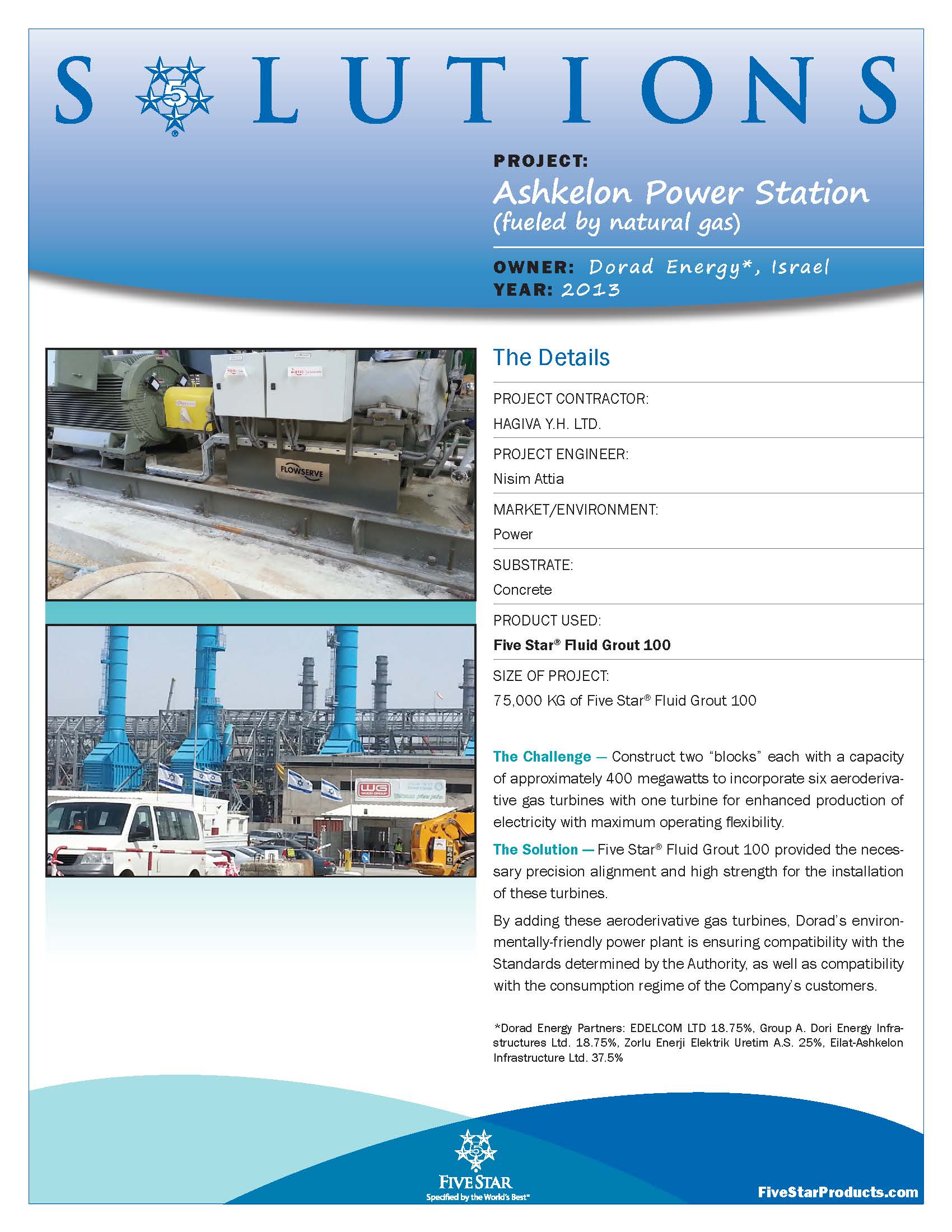

Ashkelon Power Station - Isreal

Five Star® Fluid Grout 100 was used to precisely align and securely install aeroderivative gas turbines for an environmentally-friendly power plant expansion.

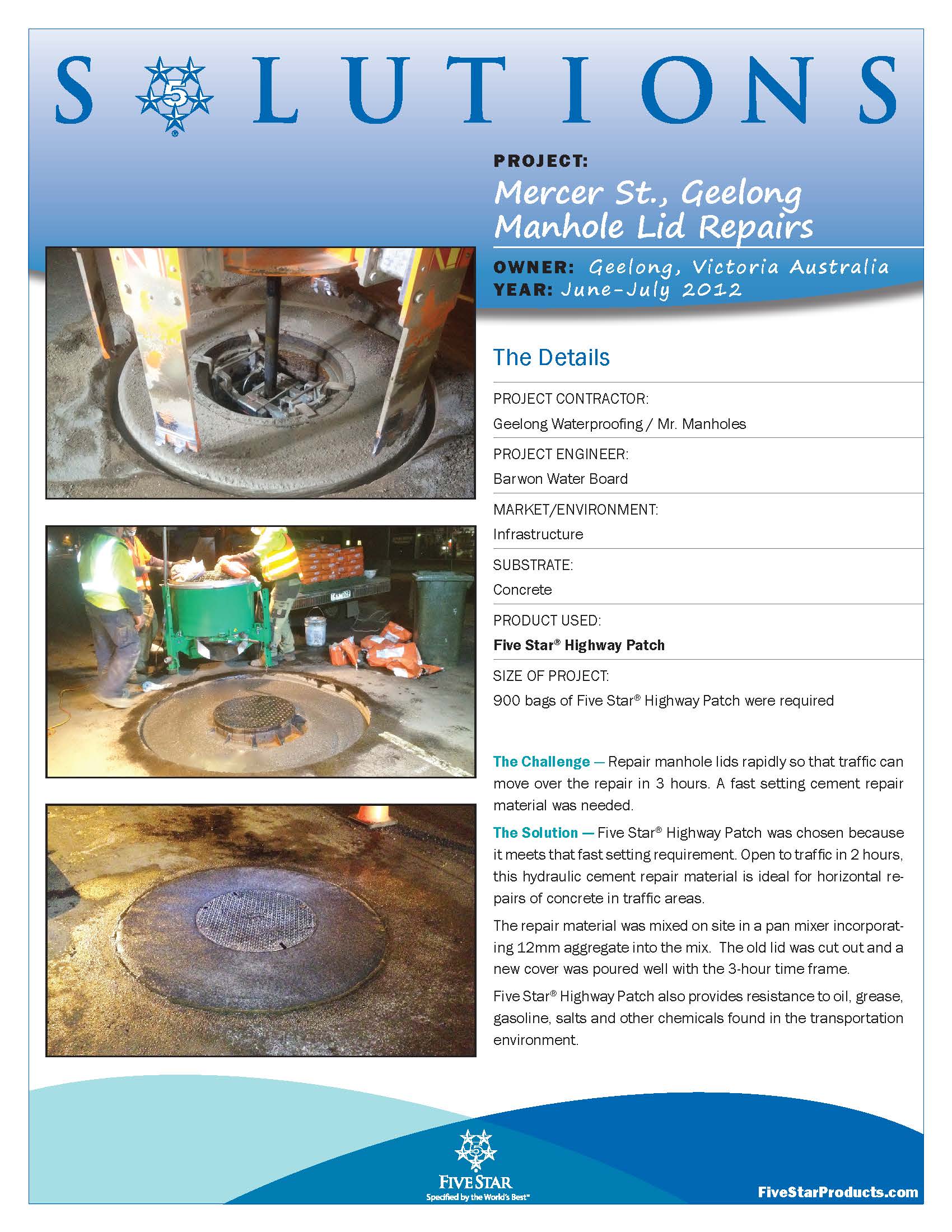

Mercer St., Geelong Manhole Lid Repairs - Victoria, Australia

To rapidly repair manhole lids for traffic readiness in 3 hours, Five Star® Highway Patch was used, setting in 2 hours and suitable for horizontal traffic area repairs. The product also offers resistance to common roadway chemicals.

New Afton Gold Mine - Canada

For the installation of pads under various drive components, Five Star® DP Epoxy Grout High Flow was chosen for its alignment and support capabilities. The site's general contractor appreciated the product's easy mixing, cleanup, and flow.

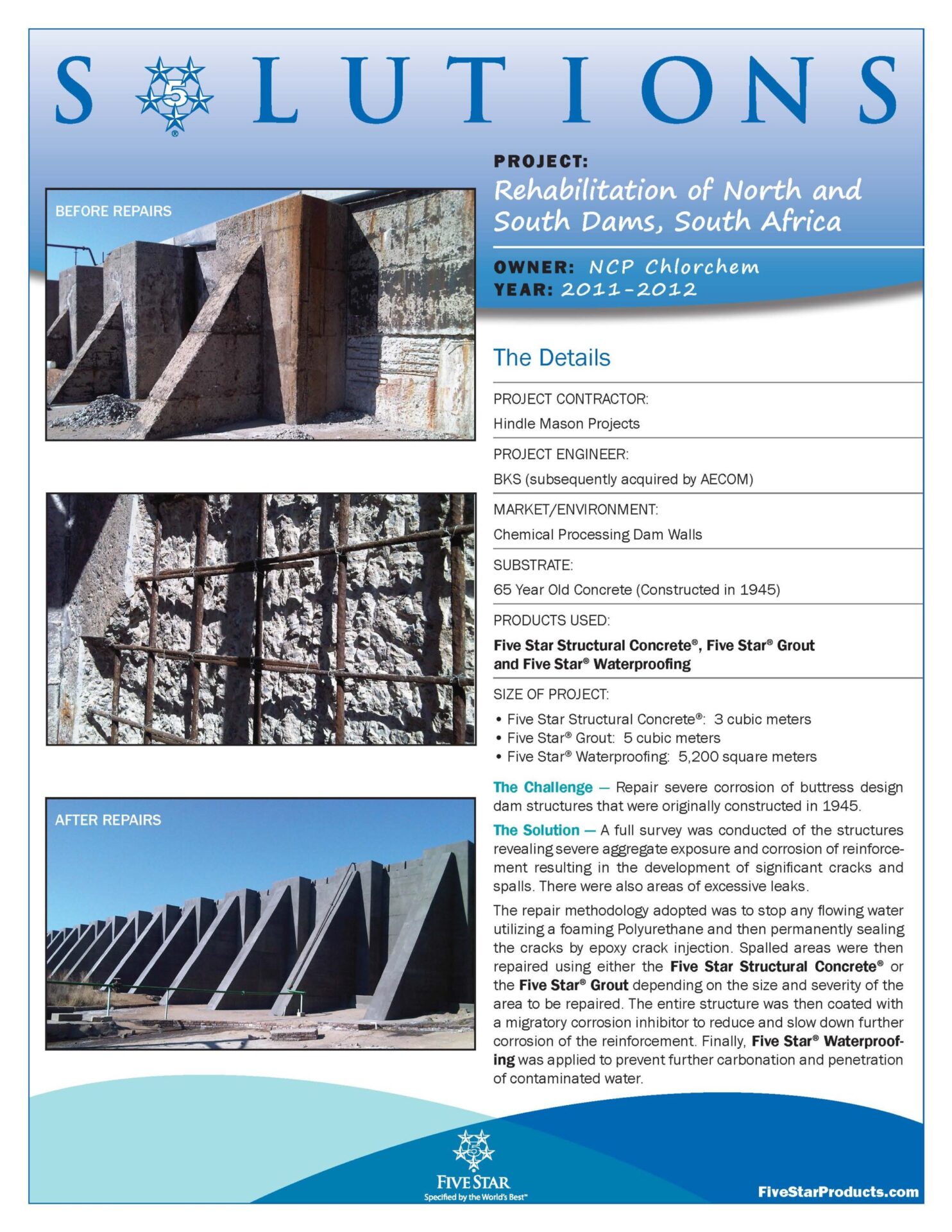

Rehabilitation of North and South Dams - South Africa

To repair the corroded dam structures from 1945, flowing water was halted using Polyurethane, cracks sealed with epoxy, and spalls fixed using Five Star Structural Concrete® or Five Star® Grout. The dam was treated with corrosion inhibitors and Five Star® Waterproofing for added protection.

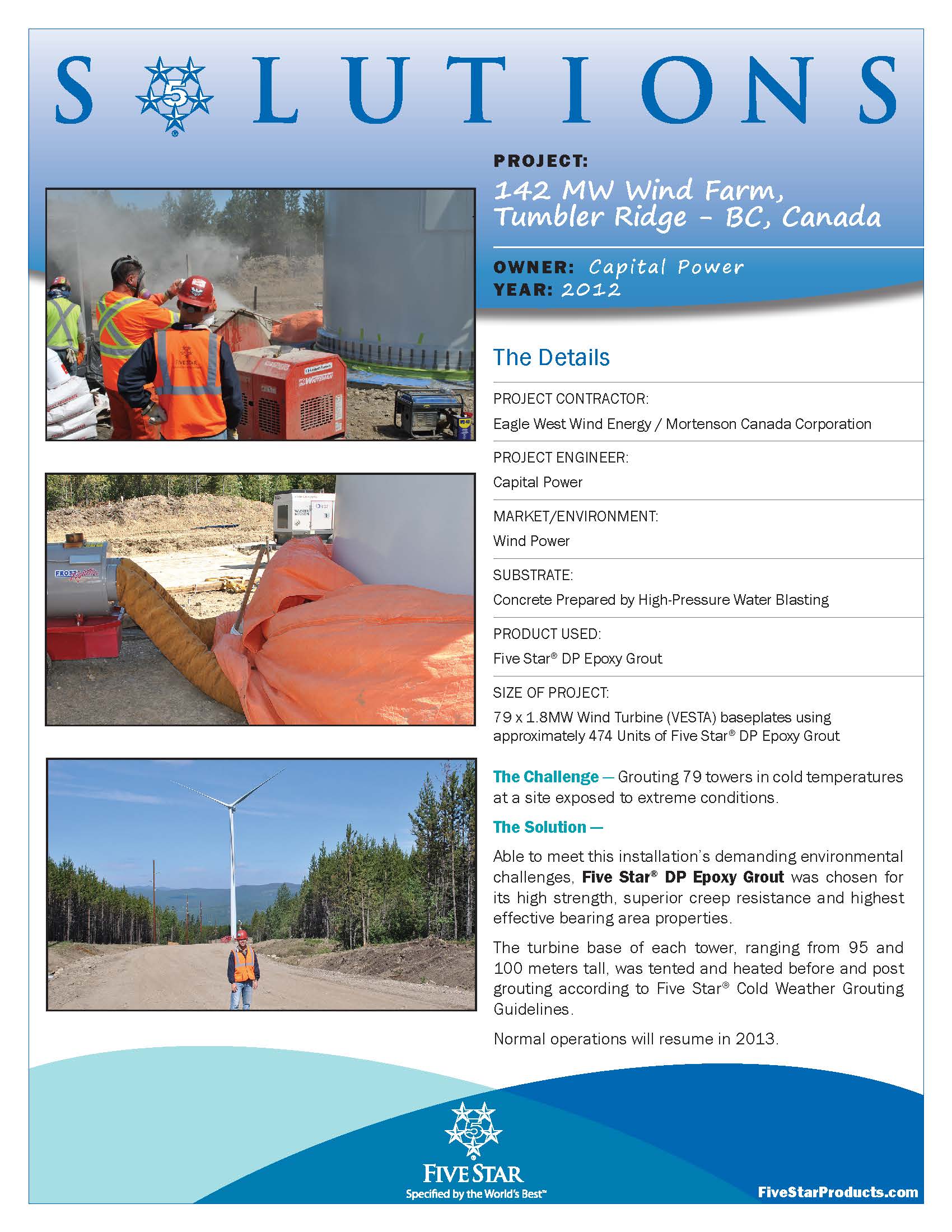

142 MW Wind Farm, Tumbler Ridge - BC, Canada

In extremely cold conditions, Five Star® DP Epoxy Grout was selected to grout 79 towers due to its high strength and creep resistance. Each turbine base was tented and heated before and after grouting according to Five Star® Cold Weather Grouting Guidelines.

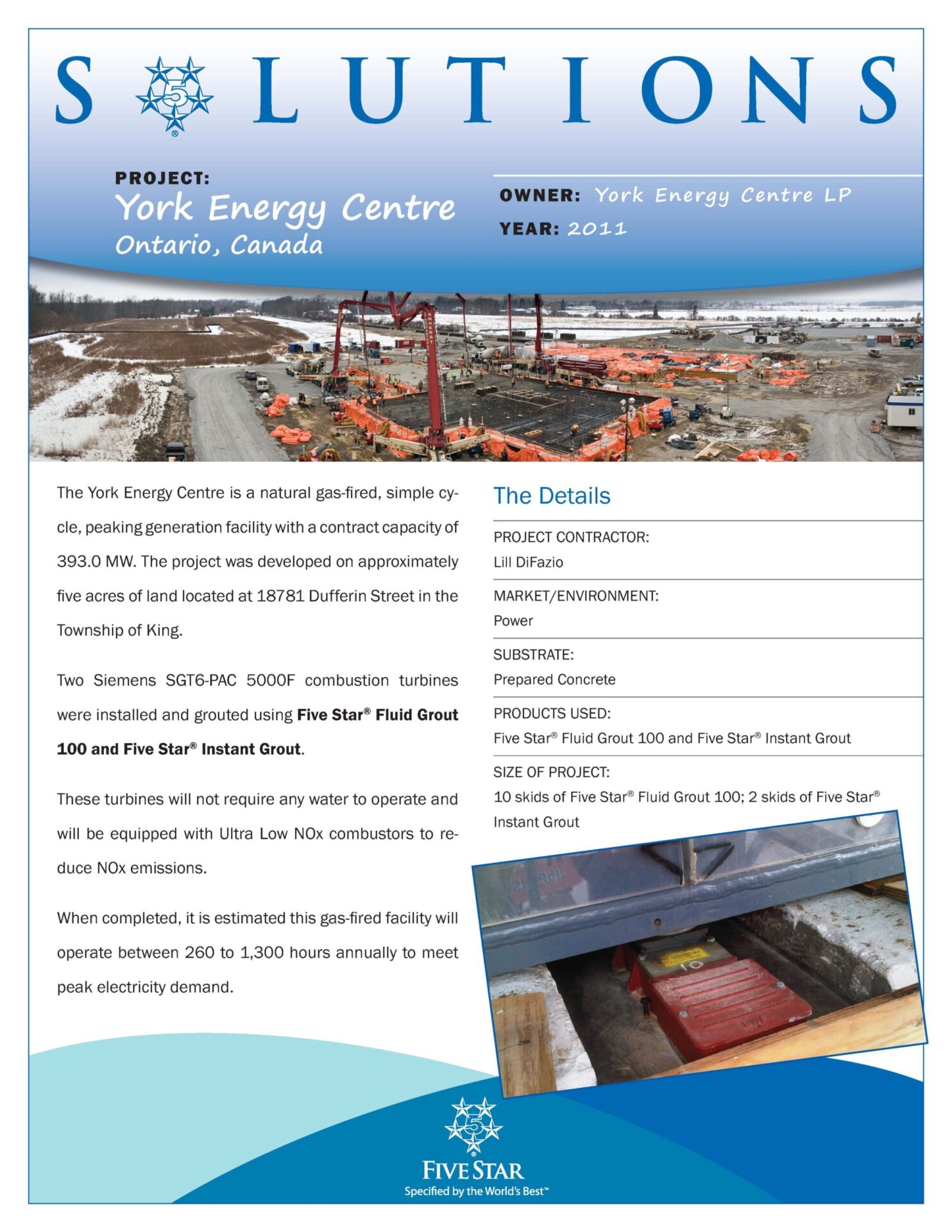

York Energy Centre - Ontario, Canada

The products, Five Star® Fluid Grout 100 and Five Star® Instant Grout, were used to anchor two Siemens SGT6-PAC 5000F combustion turbines at the York Energy Centre.

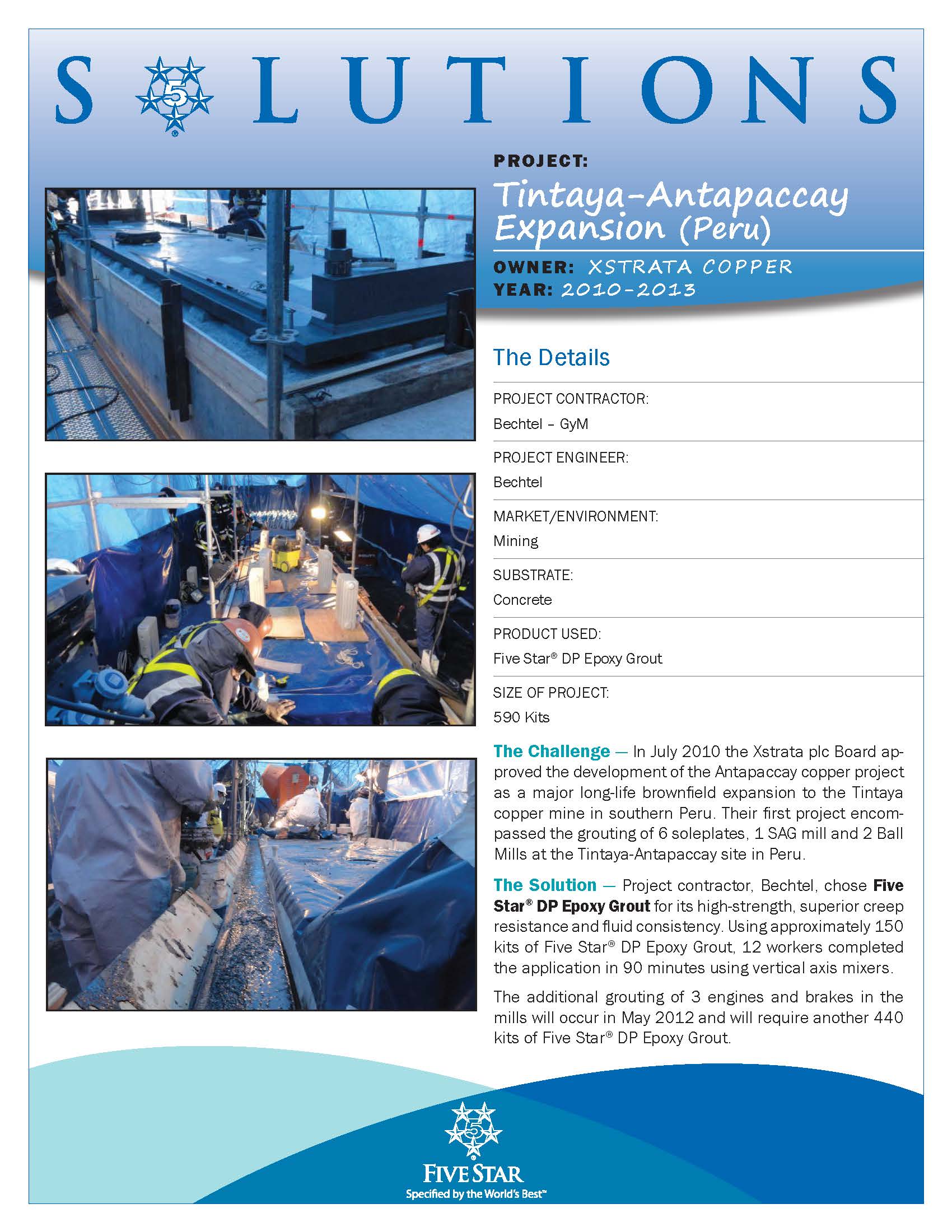

XSTRATA Copper Tintaya-Antapaccay Expansion - Peru

Project contractor Bechtel chose Five Star® DP Epoxy Grout for grouting projects at this major long-life brownfield expansion to the Tintaya copper mine.